loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1 月 . 24, 2025 01:17

Back to list

frp sand filter vessel

The rapid advancement of technologies in water filtration has brought about a paradigm shift, highlighting the efficacy of FRP sand filter vessels in the realm of industrial, commercial, and municipal applications. These vessels stand as a testament to engineering innovation, integrating seamlessly with various water treatment systems to provide consistent, high-quality filtration results. The expertise required to optimize these systems for maximum efficiency, combined with the reliability they offer, makes them a preferred choice in diverse sectors.

Balancing the integrity of the FRP sand filter vessels involves regular monitoring to ensure peak performance levels. Implementing advanced monitoring systems that track flow rates, pressure levels, and filter media conditions is essential. These intelligent systems help in preempting potential downtimes or inefficiencies by providing actionable insights into the health of the filtration process. This expert approach not only safeguards operational stability but also extends the life of the filter media and the vessels themselves. Authoritative insights into the use of FRP sand filter vessels also emphasize their environmental impact—or rather, the lack thereof. Unlike certain materials that may leach harmful substances into the environment over time, FRP vessels boast an environmentally friendly profile. Their long lifespan reduces the frequency of replacement, minimizing waste and promoting sustainable operational practices. This eco-friendly appeal is increasingly important in a world striving to embrace green technologies across all industrial domains. In ensuring trustworthiness, manufacturers of FRP sand filter vessels adhere to stringent international standards and regulations, which guarantee the reliability and safety of these systems. Independent testing and quality control measures further affirm their legitimacy and performance standards. When selecting a supplier, opting for those with a proven track record and compliance with ISO, NSF, or other relevant certifications provides additional peace of mind for stakeholders concerned with safety and regulatory adherence. In conclusion, the embrace of FRP sand filter vessels within water filtration processes signifies a confluence of cutting-edge material science and practical engineering. Their advantages in terms of durability, efficiency, and environmental compliance are well-supported by industry experts, making them a top choice for organizations aiming to refine their water management strategies. Through rigorous professional expertise and adherence to authoritative standards, these vessels promise both reliability and enhanced operational trustworthiness in an ever-evolving technological landscape.

Balancing the integrity of the FRP sand filter vessels involves regular monitoring to ensure peak performance levels. Implementing advanced monitoring systems that track flow rates, pressure levels, and filter media conditions is essential. These intelligent systems help in preempting potential downtimes or inefficiencies by providing actionable insights into the health of the filtration process. This expert approach not only safeguards operational stability but also extends the life of the filter media and the vessels themselves. Authoritative insights into the use of FRP sand filter vessels also emphasize their environmental impact—or rather, the lack thereof. Unlike certain materials that may leach harmful substances into the environment over time, FRP vessels boast an environmentally friendly profile. Their long lifespan reduces the frequency of replacement, minimizing waste and promoting sustainable operational practices. This eco-friendly appeal is increasingly important in a world striving to embrace green technologies across all industrial domains. In ensuring trustworthiness, manufacturers of FRP sand filter vessels adhere to stringent international standards and regulations, which guarantee the reliability and safety of these systems. Independent testing and quality control measures further affirm their legitimacy and performance standards. When selecting a supplier, opting for those with a proven track record and compliance with ISO, NSF, or other relevant certifications provides additional peace of mind for stakeholders concerned with safety and regulatory adherence. In conclusion, the embrace of FRP sand filter vessels within water filtration processes signifies a confluence of cutting-edge material science and practical engineering. Their advantages in terms of durability, efficiency, and environmental compliance are well-supported by industry experts, making them a top choice for organizations aiming to refine their water management strategies. Through rigorous professional expertise and adherence to authoritative standards, these vessels promise both reliability and enhanced operational trustworthiness in an ever-evolving technological landscape.

Share

Next:

Latest news

-

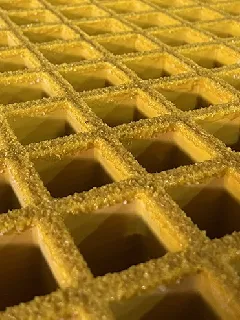

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024