loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

FRP Sand Filtration Vessel for Efficient Water Purification Solutions

Understanding FRP Sand Filter Vessels

FRP (Fiber Reinforced Plastic) sand filter vessels are essential components in various water treatment processes. These vessels are notable for their durability and efficient filtration capabilities, making them an increasingly popular choice in both industrial and municipal water treatment systems.

What Is an FRP Sand Filter Vessel?

An FRP sand filter vessel is a container made from fiber-reinforced plastic, specifically designed to hold sand and other filtration media. These vessels are typically used in applications where the separation of solid particles from water is required. The design includes a structured framework that allows for effective flow of water while also providing ample support for the media contained within.

The use of FRP materials offers multiple advantages. Unlike traditional materials such as steel or concrete, FRP vessels are resistant to corrosion, much lighter in weight, and easier to install. This makes them particularly valuable in areas where traditional materials would deteriorate due to harsh environmental conditions or chemicals present in water.

The Role of Sand Filters in Water Treatment

Sand filtration is a crucial step in water treatment processes. Sand filters are used to remove suspended solids, turbidity, and various microorganisms from water. This process is vital for both potable water production and wastewater treatment.

In a sand filter vessel, water flows through layers of sand. The sand particles act as a physical barrier, trapping particles and contaminants as water passes through. Over time, as the sand becomes clogged with particulates, the efficiency of the filter diminishes. Therefore, regular maintenance and backwashing are necessary to ensure optimal performance.

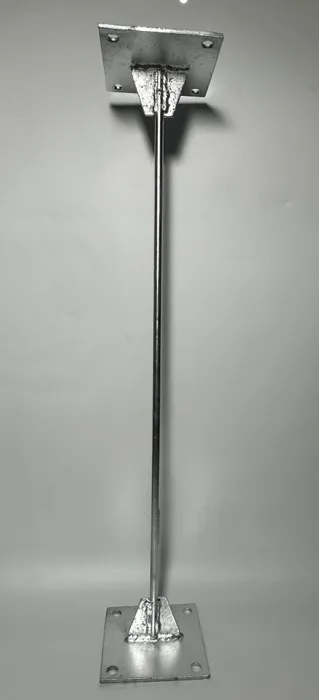

frp sand filter vessel

Benefits of Using FRP Sand Filter Vessels

1. Corrosion Resistance FRP vessels are highly resistant to corrosion, allowing them to withstand harsh chemicals and environmental conditions sustainably.

2. Lightweight and Easy to Install Being significantly lighter than conventional materials, FRP sand filter vessels are easier to transport and install. This can result in reduced labor costs and quicker installation time.

3. Enhanced Strength FRP materials provide excellent structural integrity. Therefore, these vessels can operate under high pressures and heavy loads, making them suitable for various applications.

4. Customizable FRP vessels can be manufactured in different sizes and configurations to meet specific operational requirements. This flexibility allows for integration into a wide range of water treatment systems.

5. Cost-Effective While the initial cost of FRP vessels may be higher than traditional materials, their longevity and lower maintenance costs can lead to significant savings in the long run.

Conclusion

FRP sand filter vessels play an indispensable role in modern water treatment processes. Their unique properties make them an attractive alternative to conventional materials, providing robust and effective solutions for filtration needs. As industries and municipalities continue to prioritize sustainable practices, the use of FRP vessels will likely grow, supporting the increasing demand for clean and safe water. As technology advances, further enhancements in design and material properties may enhance their efficiency and applicability even further, ensuring their relevance in the future of water treatment.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024