loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 02, 2025 01:16

Back to list

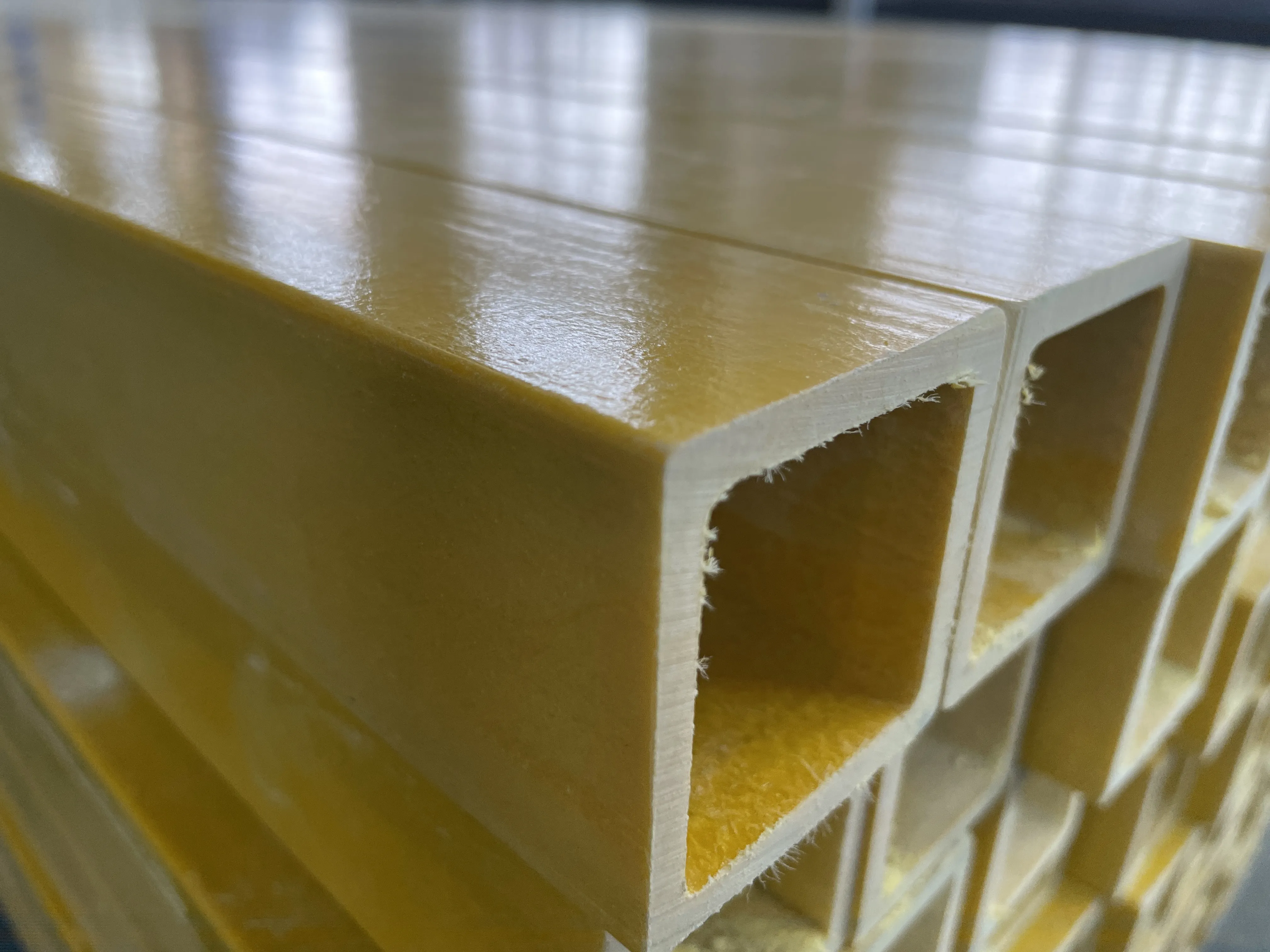

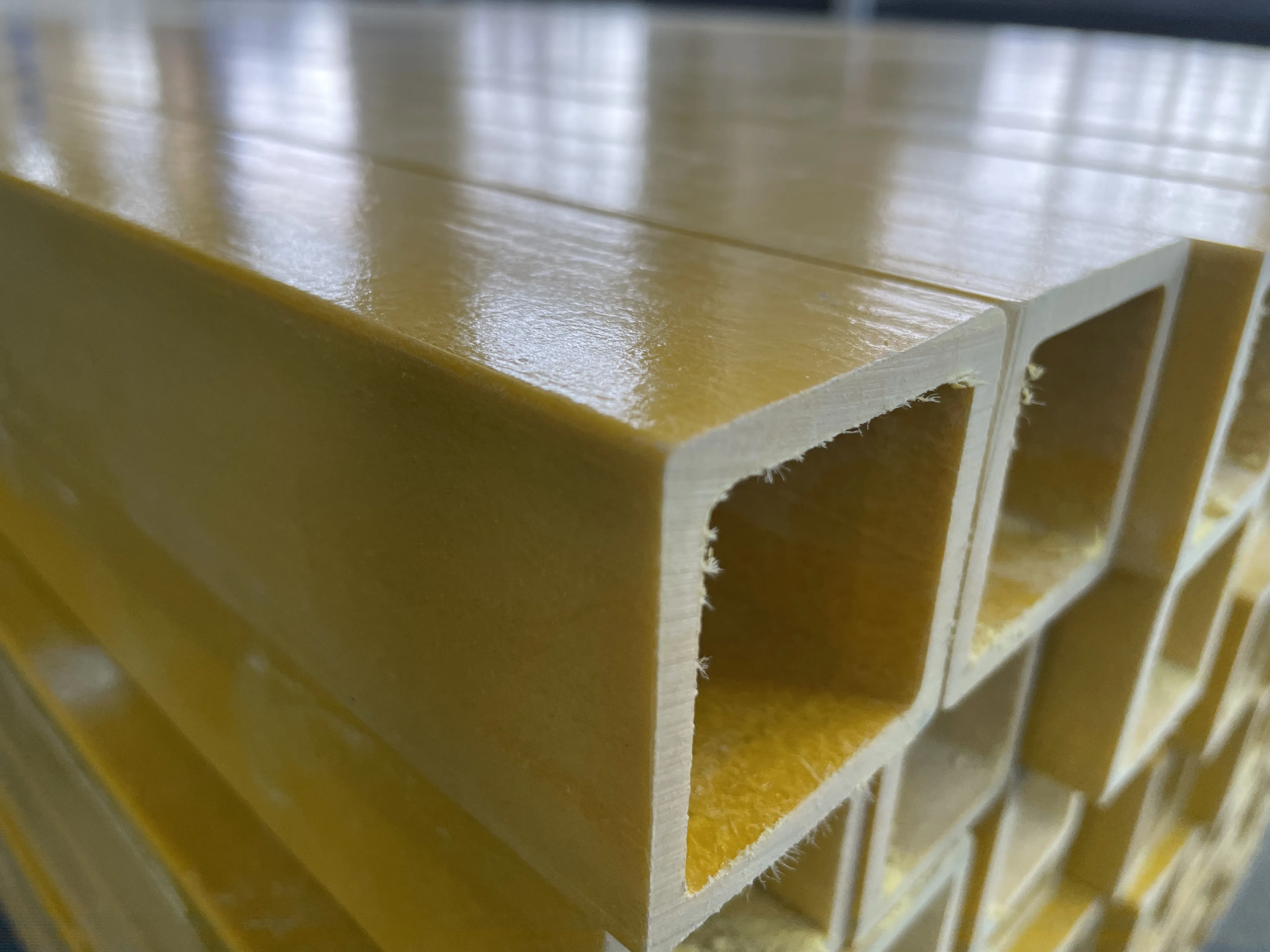

frp square tube

FRP square tubes have emerged as pivotal components in a range of industrial and architectural applications, thanks to their exceptional properties and versatility. These cutting-edge structural materials, crafted from Fiberglass Reinforced Plastic (FRP), offer advantages that transcend traditional materials like steel and aluminum. This article delves into the unmatched experience, expertise, authoritativeness, and trustworthiness embedded in the use of FRP square tubes, positioning them as vital assets in modern engineering solutions.

From an authoritative standpoint, the credibility of FRP square tubes is validated through rigorous testing and compliance with international standards. Products manufactured and utilized globally meet rigorous ASTM, ISO, and other certifying bodies' criteria, underscoring their reliability and efficacy. Leading manufacturers provide comprehensive data sheets and technical support, ensuring that decision-makers have access to all necessary information for informed choices. This ensures that every tube used in construction or design respects the safety margins and operational expectations demanded by industry best practices. Trust is at the core of selecting materials for construction, and FRP square tubes have consistently proven their merit over decades of usage across varied domains. Case studies from aerospace to civil engineering illustrate not only functional success but also economic viability—reducing maintenance expenditures and offering a favorable life-cycle cost compared to traditional materials. Stakeholders in various sectors heavily rely on feedback and accumulated positive experiences from peer installations, further consolidating the trust placed in FRP solutions. In conclusion, FRP square tubes redefine structural possibilities, combining performance, durability, and adaptability with the backing of extensive research and industry endorsement. Their application not only meets current engineering demands but anticipates future innovations in sustainable and efficient material science. Professionals in engineering and design should consider FRP square tubes as future-forward materials, pivotal in achieving both creative and practical objectives in global construction paradigms.

From an authoritative standpoint, the credibility of FRP square tubes is validated through rigorous testing and compliance with international standards. Products manufactured and utilized globally meet rigorous ASTM, ISO, and other certifying bodies' criteria, underscoring their reliability and efficacy. Leading manufacturers provide comprehensive data sheets and technical support, ensuring that decision-makers have access to all necessary information for informed choices. This ensures that every tube used in construction or design respects the safety margins and operational expectations demanded by industry best practices. Trust is at the core of selecting materials for construction, and FRP square tubes have consistently proven their merit over decades of usage across varied domains. Case studies from aerospace to civil engineering illustrate not only functional success but also economic viability—reducing maintenance expenditures and offering a favorable life-cycle cost compared to traditional materials. Stakeholders in various sectors heavily rely on feedback and accumulated positive experiences from peer installations, further consolidating the trust placed in FRP solutions. In conclusion, FRP square tubes redefine structural possibilities, combining performance, durability, and adaptability with the backing of extensive research and industry endorsement. Their application not only meets current engineering demands but anticipates future innovations in sustainable and efficient material science. Professionals in engineering and design should consider FRP square tubes as future-forward materials, pivotal in achieving both creative and practical objectives in global construction paradigms.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024