loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 16, 2025 07:00

Back to list

frp vessel for water treatment

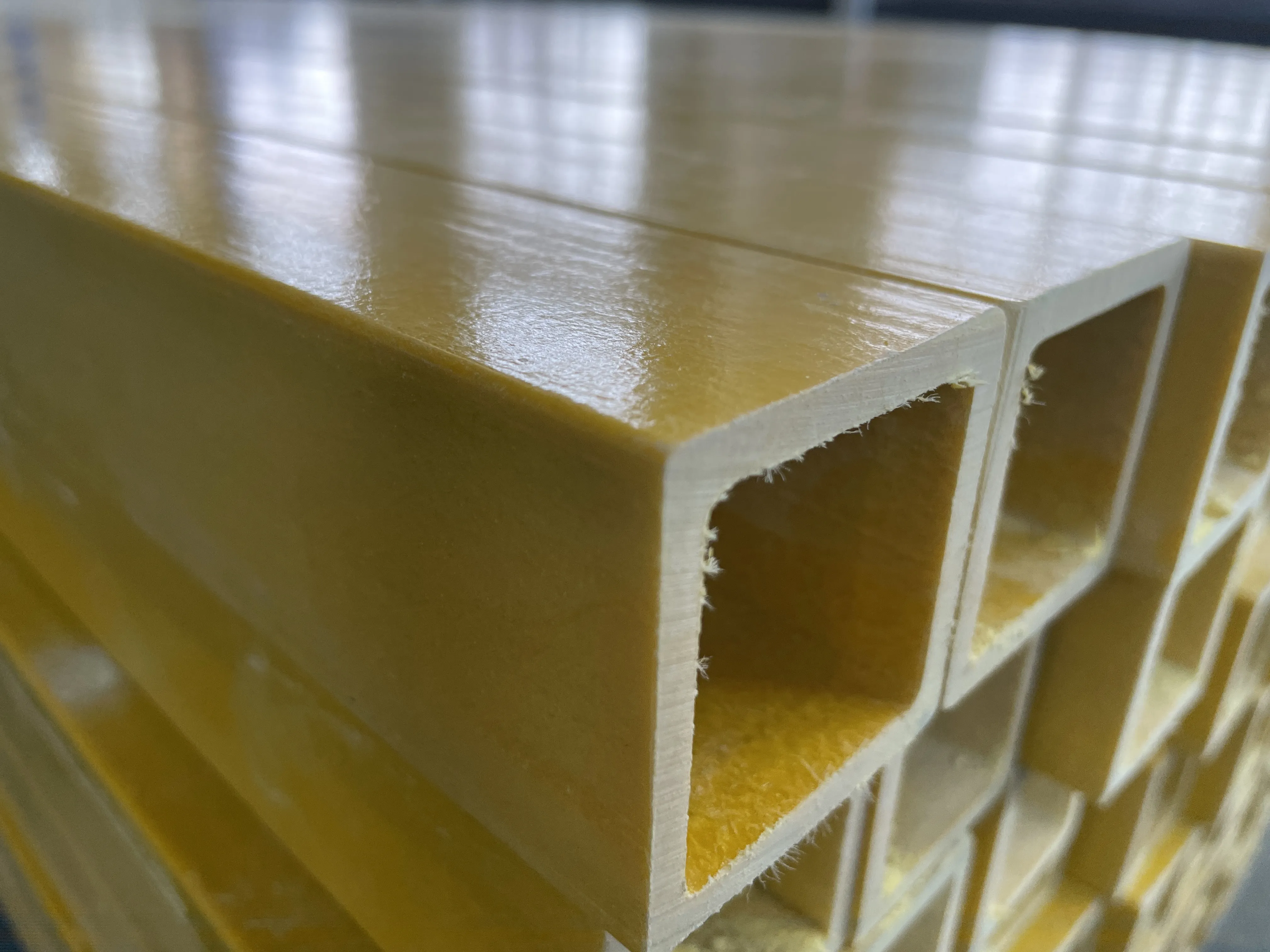

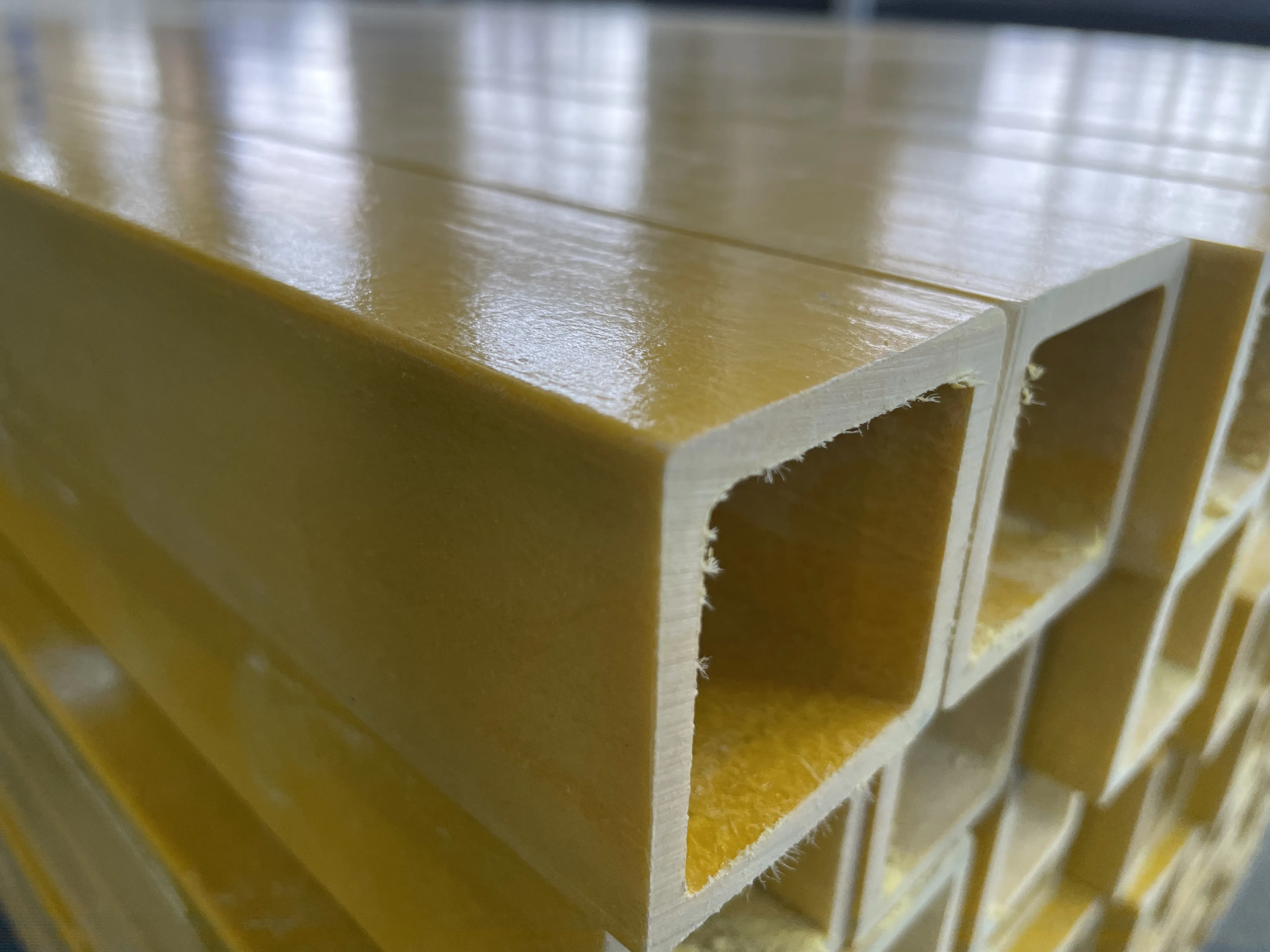

In the evolving world of construction and engineering, the FRP square tube has emerged as a game-changing material, offering unparalleled advantages across various industries. FRP, or Fiber Reinforced Plastic, is a composite material made of a polymer matrix reinforced with fibers. This material has permeated diverse applications due to its unique properties, blending strength, resilience, and versatility.

In terms of trustworthiness, FRP square tubes are extensively tested to meet stringent industry standards. The assurance of quality through rigorous testing for flammability, smoke emission, and strength makes them a reliable material choice. Trust in their performance is reinforced by their widespread adoption in critical infrastructure projects worldwide. As such, businesses and governments entrust their most critical construction needs to FRP solutions, knowing they will stand the test of time. FRP square tubes also offer unmatched versatility. They can be easily molded into various shapes and sizes to suit specific project requirements, offering flexibility in design. This adaptability is a boon to architects and designers who seek to push the boundaries of conventional structures. Additionally, the aesthetic appeal of FRP tubes cannot be overlooked; they can be manufactured in a range of colors and finishes, contributing to both the form and function of a project. With sustainability being a core focus in modern construction, FRP tubes contribute positively due to their long life cycle and recyclability. The minimal environmental impact during production and their potential for reuse underline their role in constructing a sustainable future. Companies aiming to reduce their carbon footprint increasingly turn to FRP as a viable alternative to more traditional, resource-intensive materials. In conclusion, the FRP square tube stands as a testament to innovation in materials science, offering a blend of durability, strength, adaptability, and efficiency. Its widespread acceptance and continued use signal a shift towards strategies that prioritize longevity, safety, and environmental responsibility. As industries progress, adopting advanced materials like FRP square tubes could be the key to unlocking sustainable and efficient engineering solutions.

In terms of trustworthiness, FRP square tubes are extensively tested to meet stringent industry standards. The assurance of quality through rigorous testing for flammability, smoke emission, and strength makes them a reliable material choice. Trust in their performance is reinforced by their widespread adoption in critical infrastructure projects worldwide. As such, businesses and governments entrust their most critical construction needs to FRP solutions, knowing they will stand the test of time. FRP square tubes also offer unmatched versatility. They can be easily molded into various shapes and sizes to suit specific project requirements, offering flexibility in design. This adaptability is a boon to architects and designers who seek to push the boundaries of conventional structures. Additionally, the aesthetic appeal of FRP tubes cannot be overlooked; they can be manufactured in a range of colors and finishes, contributing to both the form and function of a project. With sustainability being a core focus in modern construction, FRP tubes contribute positively due to their long life cycle and recyclability. The minimal environmental impact during production and their potential for reuse underline their role in constructing a sustainable future. Companies aiming to reduce their carbon footprint increasingly turn to FRP as a viable alternative to more traditional, resource-intensive materials. In conclusion, the FRP square tube stands as a testament to innovation in materials science, offering a blend of durability, strength, adaptability, and efficiency. Its widespread acceptance and continued use signal a shift towards strategies that prioritize longevity, safety, and environmental responsibility. As industries progress, adopting advanced materials like FRP square tubes could be the key to unlocking sustainable and efficient engineering solutions.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024