loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

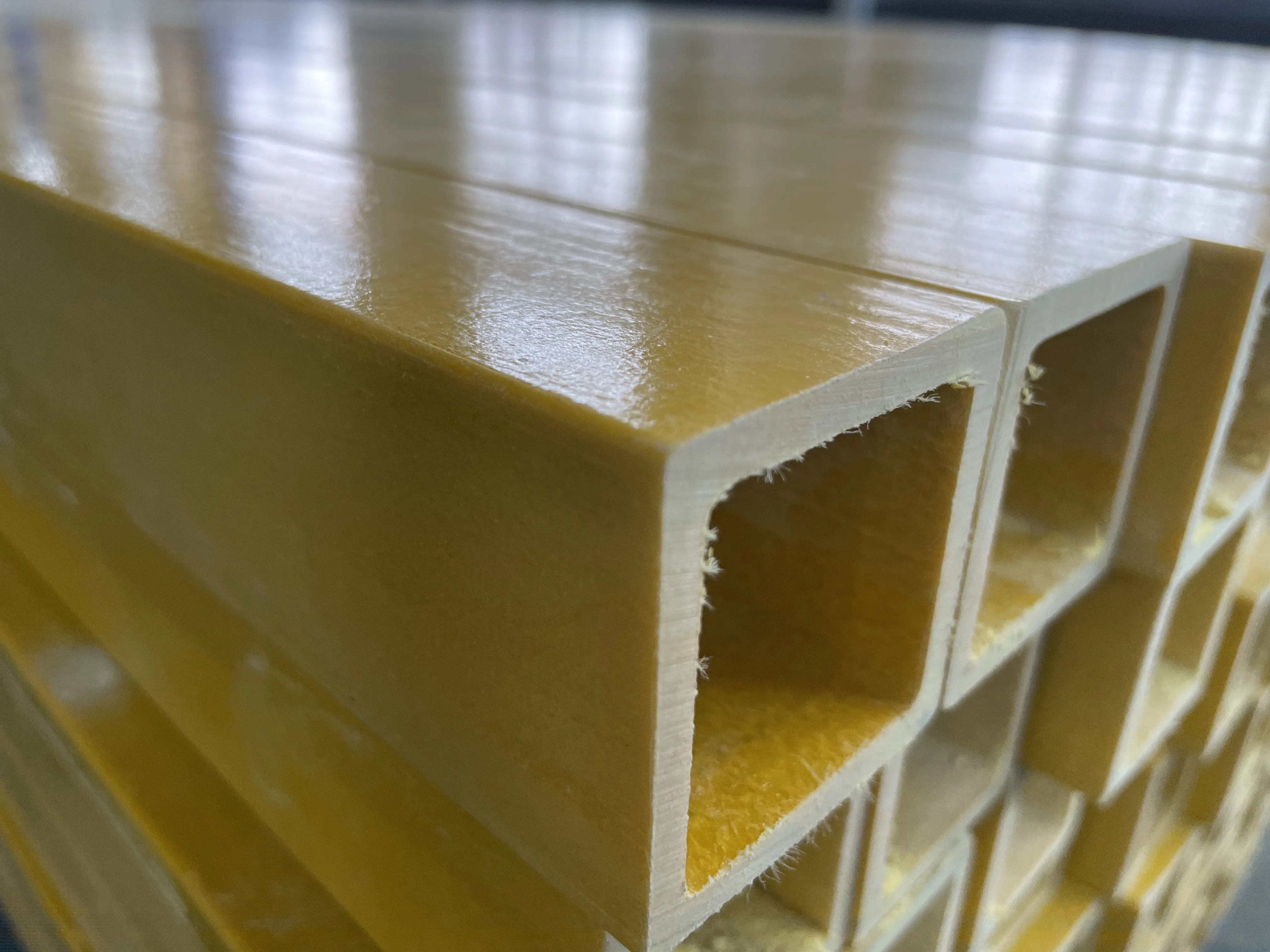

Exploring the Benefits of FRP Square Tubes in Construction and Design

Understanding FRP Square Tubes Applications, Benefits, and Manufacturing Process

In the realm of modern construction and engineering materials, Fiber Reinforced Polymer (FRP) square tubes are gaining significant traction due to their unique properties and advantages over traditional materials like steel and aluminum. These composite materials, combining polymer matrices with reinforcing fibers, present a transformative option for various applications across industries.

What Are FRP Square Tubes?

FRP square tubes are structural components made from a composite material that consists of a polymer matrix reinforced with fibers, such as glass, carbon, or aramid. The square shape of these tubes provides enhanced stability and strength for various applications. They are designed to withstand significant loads while being lightweight, making them an ideal choice for sectors requiring durable and efficient materials.

Key Benefits of FRP Square Tubes

1. Lightweight One of the most significant advantages of FRP square tubes is their low weight compared to traditional metals. This characteristic not only reduces transportation costs but also simplifies installation procedures, allowing for easier handling and assembly.

2. Corrosion Resistance FRP materials are inherently resistant to corrosion, which makes them suitable for applications in harsh environments, such as marine and chemical processing industries. This quality eliminates the need for protective coatings, reducing maintenance costs and extending the lifespan of the structures.

3. High Strength-to-Weight Ratio FRP square tubes exhibit exceptional strength for their weight. Their ability to bear heavy loads while remaining lightweight makes them an ideal solution for structural applications, including bridges, frameworks, and supports.

4. Thermal and Electrical Insulation Unlike metals, FRP materials act as insulators against both electricity and heat. This property is particularly beneficial in applications where electrical or thermal conductivity could pose safety risks or lead to energy inefficiency.

5. Design Flexibility FRP square tubes offer significant design flexibility. They can be manufactured in various sizes, shapes, and colors to meet specific aesthetic and functional requirements. This versatility allows architects and designers to implement innovative and customized solutions.

Applications of FRP Square Tubes

FRP square tubes have found applications across multiple industries

- Construction These tubes are extensively used in building frames, bridges, and support structures where corrosion resistance and lightweight properties are crucial.

frp square tube

- Transportation In the automotive and aerospace sectors, FRP square tubes are employed to create lightweight components, contributing to fuel efficiency and performance.

- Marine Industry The maritime sector utilizes FRP square tubes for boat frameworks and docks, where exposure to saltwater necessitates materials that can withstand corrosion.

- Renewable Energy In wind and solar energy applications, FRP square tubes are used to produce lightweight structures, improving the overall efficiency of energy generation.

- Sports Equipment The athletic sector incorporates these tubes into sports equipment, such as cycling frames and other gear, where high strength and durability are required.

Manufacturing Process of FRP Square Tubes

The manufacturing of FRP square tubes involves several critical steps

1. Material Selection The first step is the selection of the appropriate polymer matrix and reinforcement fibers based on the desired properties of the final product.

2. Pultrusion Process This common method for producing FRP square tubes involves pulling continuous fibers through a resin bath and then through a heated die, where the tube is formed and cured simultaneously.

3. Curing After shaping, the composite material is cured, allowing the resin to harden and bond with the fiber reinforcement, resulting in a solid and durable product.

4. Cutting and Finishing The cured tubes are cut to the required lengths and may undergo additional finishing processes such as sanding, painting, or coating to meet specific aesthetic or functional requirements.

Conclusion

FRP square tubes represent a significant advancement in material science, offering unparalleled benefits for a wide range of applications. Their lightweight nature, corrosion resistance, high strength, and design flexibility position them as a superior choice for contemporary construction and engineering challenges. As industries increasingly prioritize sustainability and efficiency, FRP square tubes are poised to play a pivotal role in the future of material innovation. With ongoing advancements in manufacturing processes and material technology, the potential applications of FRP are bound to expand, leading to smarter, more durable structures that meet the demands of a changing world.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024