loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Price Trends for FRP Square Tubes in Today's Market

Understanding the Price Dynamics of FRP Square Tubes

Fiber Reinforced Polymer (FRP) square tubes have gained popularity in various construction and engineering applications due to their exceptional strength-to-weight ratio, corrosion resistance, and versatility. As industries continue to seek lighter and more durable materials, the demand for FRP square tubes has surged, leading to a nuanced landscape of pricing that potential buyers must navigate.

What are FRP Square Tubes?

FRP square tubes are composite materials made from a polymer matrix reinforced with fibers, most commonly fiberglass or carbon fiber. The resulting product boasts excellent mechanical properties, making it suitable for use in construction, automotive, aerospace, and marine applications. The lightweight nature of FRP square tubes makes them easier to handle and install compared to traditional materials like steel or aluminum, potentially offsetting labor costs.

Factors Influencing Pricing

Several factors influence the pricing of FRP square tubes, all of which buyers should consider when making purchasing decisions.

1. Material Composition The type of fibers used in the reinforcement significantly affects the price. Carbon fiber, for instance, is more expensive than fiberglass due to its superior strength and lightweight properties. Consequently, products made with carbon fiber typically command higher prices.

2. Manufacturing Processes The method used to produce FRP square tubes can vary, with processes such as pultrusion, resin transfer molding (RTM), and filament winding being common. Each method has different costs associated with raw materials, labor, and energy consumption, which ultimately impact the final market price.

frp square tube price

3. Size and Customization FRP square tubes come in various sizes, and custom orders can further influence cost. Standard sizes may be cheaper due to economies of scale during production, while custom dimensions can result in increased production time and materials, raising prices.

4. Market Demand The overall demand for FRP products can fluctuate based on economic conditions, technological advancements, and the growth of sectors like renewable energy and infrastructure development. Higher demand often leads to increased prices, especially if supply chain disruptions occur.

5. Supplier Relationship Building a good relationship with suppliers can also lead to price advantages. Long-term contracts or bulk purchasing can sometimes result in discounts. On the other hand, sourcing from multiple suppliers may lead to a wider price range.

Comparative Pricing with Traditional Materials

When weighing the cost of FRP square tubes against traditional materials, it’s essential to consider not just the raw material prices but also the total cost of ownership. While FRP square tubes may have a higher upfront cost compared to steel or aluminum, their longevity, reduced maintenance needs, and resistance to corrosion can lead to cost savings over time. Furthermore, their lightweight nature reduces transportation and installation costs, making them economically viable in the long run.

Conclusion

In conclusion, the price of FRP square tubes is influenced by various factors, including material type, manufacturing processes, market demand, and supplier relationships. For businesses and industries looking to invest in these materials, it is crucial to consider both immediate costs and long-term benefits. As technology advances and production methods continue to improve, prices may become more competitive, making FRP square tubes an increasingly appealing option in a variety of applications. Understanding the market dynamics and evaluating the total cost of ownership will empower buyers to make informed decisions that align with their project needs and budget constraints.

-

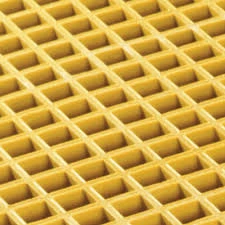

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024