loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

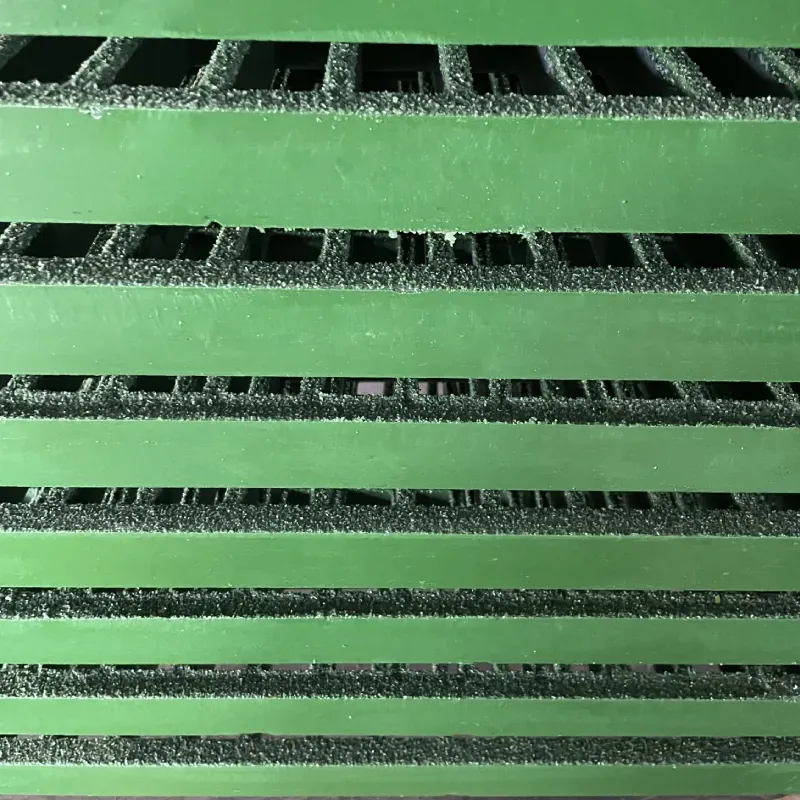

frp steel structure

The Role of FRP in Steel Structure Construction

Fiber Reinforced Polymer (FRP) has emerged as a revolutionary material in the construction industry, especially in the context of steel structures. As the demand for innovative and sustainable building materials increases, engineers and architects are increasingly turning to FRP due to its unique properties and advantages over traditional materials.

FRP is a composite material made of a polymer matrix reinforced with fibers, typically glass, carbon, or aramid. This combination results in a lightweight yet exceptionally strong material that boasts high resistance to corrosion, chemical attack, and fatigue. These characteristics make FRP an ideal candidate for enhancing steel structures, which can often be vulnerable to such challenges.

The Role of FRP in Steel Structure Construction

Moreover, FRP's resistance to corrosion significantly extends the lifespan of steel structures. Traditional steel is susceptible to rusting, especially in environments prone to moisture and chemical exposure. This corrosion can lead to structural integrity problems over time. By reinforcing steel with FRP, the durability of the structure is greatly enhanced, resulting in lower maintenance costs and longer service life. This is particularly beneficial in harsh environments such as coastal areas and industrial settings where exposure to chemicals and saltwater is prevalent.

frp steel structure

FRP also offers versatility in design. The material can be molded into various shapes and sizes, allowing architects to explore innovative designs that were previously unattainable with traditional materials. This design flexibility enables the creation of aesthetically pleasing structures that do not compromise on functionality or safety. Furthermore, the lightweight nature of FRP can facilitate more daring architectural solutions, such as cantilevered beams and complex geometries.

In terms of sustainability, FRP contributes positively to green building practices. Its long lifespan means fewer resources are needed for repairs and replacements over time. Additionally, FRP can be manufactured with recycled materials, which significantly reduces the carbon footprint associated with its production. As the construction industry becomes more environmentally conscious, the integration of materials like FRP aligns with sustainable development goals.

However, the adoption of FRP in steel structures is not without challenges. The initial cost of FRP can be higher than traditional materials, which may deter some developers. Additionally, the engineering community is continuously working on developing standardized design codes and methods for FRP applications, as its behavior under load can differ considerably from conventional materials.

In conclusion, the integration of Fiber Reinforced Polymer in steel structure construction presents numerous advantages that make it an appealing choice for modern engineering projects. With its lightweight nature, high strength, corrosion resistance, and design versatility, FRP is poised to play a significant role in the future of construction. As technology advances and knowledge expands, the use of FRP in steel structures will likely become more commonplace, paving the way for innovative and sustainable building practices.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024