loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp structural members

Understanding FRP Structural Members Revolutionizing Construction Materials

In the construction industry, the quest for stronger, lighter, and more durable materials has led to the increasing use of Fiber Reinforced Polymer (FRP) structural members. These innovative materials combine the high strength-to-weight ratio of fiber reinforcements with the corrosion resistance and lightweight nature of polymers, offering unique advantages over traditional materials such as steel and concrete. As we delve into the properties, applications, and benefits of FRP structural members, we can better appreciate their role in modern engineering and construction.

What is FRP?

Fiber Reinforced Polymer (FRP) is a composite material made of a polymer matrix reinforced with fibers. The fibers can be made from various materials such as glass, carbon, or aramid, providing distinct characteristics that can be tailored to specific applications. The combination of fibers and the polymer matrix results in a material that exhibits exceptional tensile strength, flexibility, and resistance to various environmental factors.

Properties of FRP Structural Members

FRP structural members possess several advantageous properties that make them highly valuable in construction

1. High Strength-to-Weight Ratio One of the most significant benefits of FRP is its high strength-to-weight ratio, meaning that it can support heavy loads while being significantly lighter than traditional materials. This feature reduces the overall mass of structures, leading to lower transportation costs and easier handling during construction.

2. Corrosion Resistance Unlike steel, which can succumb to rust and corrosion, FRP is highly resistant to chemical attack, moisture, and environmental degradation. This quality makes FRP structural members particularly suitable for harsh environments, such as marine applications, chemical processing facilities, and areas with high humidity.

3. Flexibility in Design FRP materials can be molded into various shapes and sizes, allowing architects and engineers to explore innovative designs that may not be feasible with traditional materials. This flexibility enables more creative and efficient structural solutions.

frp structural members

4. Low Thermal Conductivity With low thermal conductivity, FRP materials can help in managing energy efficiency within buildings, reducing heat loss and improving insulation.

Applications of FRP Structural Members

FRP structural members are used in a variety of applications across different sectors. Common uses include

- Bridges FRP is increasingly used in bridge construction due to its lightweight nature and resistance to corrosion, significantly extending the life span of bridge structures while reducing maintenance costs. - Buildings In commercial and residential construction, FRP can be utilized for beams, columns, and other structural elements, enhancing the durability and safety of the structures.

- Wind Turbines The renewable energy sector has found a reliable application for FRP in manufacturing turbine blades, where strength and lightweight properties are crucial for efficiency.

- Marine Structures Due to its excellent resistance to saltwater corrosion, FRP is commonly used in docks, piers, and other marine applications.

Conclusion

As the construction industry continues to evolve, FRP structural members stand out as a transformative material that can address many of the challenges faced in modern construction. With their remarkable properties, including strength, lightweight, flexibility, and corrosion resistance, FRP members are not only enhancing the durability of structures but also promoting innovative design solutions. As technology advances and awareness of the benefits of FRP grows, we can expect to see even wider adoption of this versatile material in building and infrastructure projects around the world, contributing to safer, more efficient, and sustainable construction practices.

-

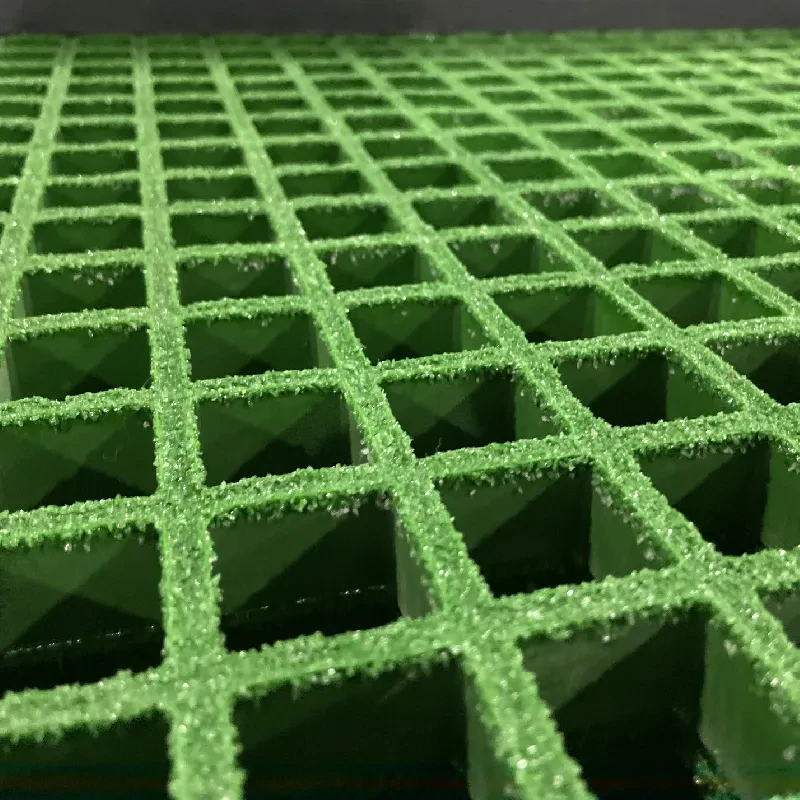

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024