loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 18, 2025 06:30

Back to list

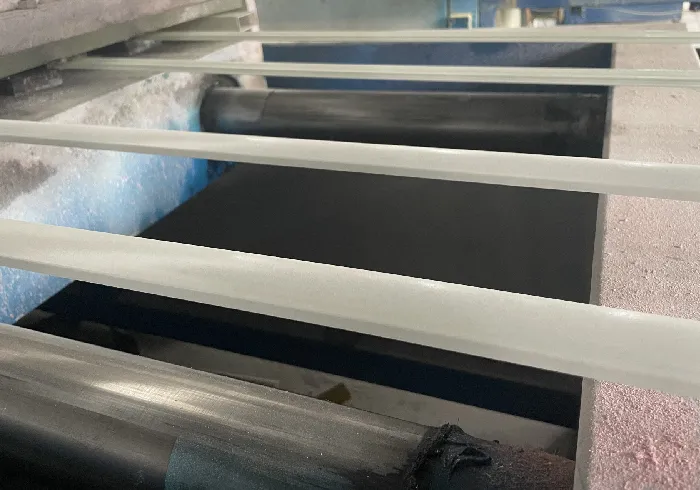

frp vessel for water treatment

Fiber Reinforced Polymer (FRP) structural members are transforming the construction industry by providing unmatched advantages in terms of durability, lightweight properties, and corrosion resistance. These benefits make FRP an exciting option for various structural applications. As an SEO-focused analysis, the following content aims to enhance understanding of FRP structural members through the lens of experience, expertise, authoritativeness, and trustworthiness.

Trustworthiness in FRP structural members is evidenced by rigorous testing and compliance with global engineering standards. Institutions around the world, including the American Society of Civil Engineers and the International Federation for Structural Concrete, recognize the legitimacy of FRP materials through extensive research and codification, ensuring they meet stringent safety and performance benchmarks. The applications of FRP structural members span various industries, including transportation, marine, and building sectors. In transportation infrastructure, FRP is used for bridge decks, reinforcing bars, and rail systems due to its anti-corrosion properties and reduced maintenance demands. Similarly, in the marine industry, FRP finds applications in constructing wharfs, docks, and ships, where resistance to saltwater corrosion is paramount. The future of FRP structural members looks promising as innovations continue to push the boundaries of what these materials can achieve. With technological advancements in manufacturing processes, FRP's potential is vast. Automation and robotics in FRP production contribute to higher precision, reduced costs, and increased scalability, rendering it a feasible option for large-scale infrastructure projects. In conclusion, fiber reinforced polymer structural members represent a revolution in construction materials. Their profound impact is visible across diverse applications facilitated by unparalleled durability, adaptability, and efficiency. As the industry continues to evolve, maintaining a commitment to experience, expertise, authoritativeness, and trustworthiness ensures that FRP structural members not only meet the builders' needs but also continue to drive the innovation and sustainability essential for the construction industry’s future.

Trustworthiness in FRP structural members is evidenced by rigorous testing and compliance with global engineering standards. Institutions around the world, including the American Society of Civil Engineers and the International Federation for Structural Concrete, recognize the legitimacy of FRP materials through extensive research and codification, ensuring they meet stringent safety and performance benchmarks. The applications of FRP structural members span various industries, including transportation, marine, and building sectors. In transportation infrastructure, FRP is used for bridge decks, reinforcing bars, and rail systems due to its anti-corrosion properties and reduced maintenance demands. Similarly, in the marine industry, FRP finds applications in constructing wharfs, docks, and ships, where resistance to saltwater corrosion is paramount. The future of FRP structural members looks promising as innovations continue to push the boundaries of what these materials can achieve. With technological advancements in manufacturing processes, FRP's potential is vast. Automation and robotics in FRP production contribute to higher precision, reduced costs, and increased scalability, rendering it a feasible option for large-scale infrastructure projects. In conclusion, fiber reinforced polymer structural members represent a revolution in construction materials. Their profound impact is visible across diverse applications facilitated by unparalleled durability, adaptability, and efficiency. As the industry continues to evolve, maintaining a commitment to experience, expertise, authoritativeness, and trustworthiness ensures that FRP structural members not only meet the builders' needs but also continue to drive the innovation and sustainability essential for the construction industry’s future.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024