loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 07, 2025 05:40

Back to list

Composite Food Grade Pressure Vessel With HDPE Inner For Water Filter

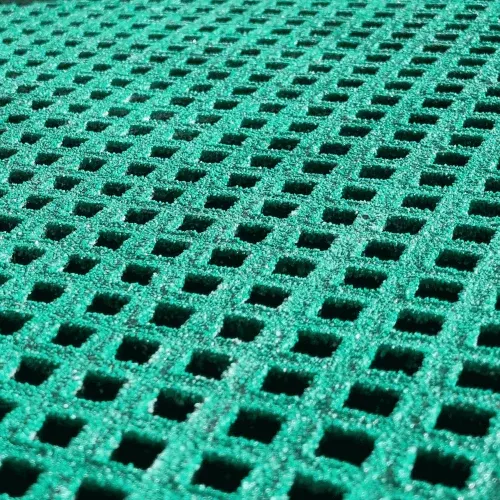

FRP (Fiber Reinforced Polymer) structural sections are revolutionizing the construction industry, offering solutions that address the limitations of traditional materials like steel, aluminum, and timber. The advanced composition of FRP incorporates high-strength fibers such as glass or carbon embedded within a polymer resin matrix, creating products that exhibit exceptional strength-to-weight ratios. This innovative material is increasingly preferred in a variety of structural applications due to its unique properties which enhance both performance and longevity.

The implementation of FRP sections in structural engineering has been supported by a growing body of research and case studies. Structural engineers and architects are increasingly gaining confidence in FRP due to rigorous testing and real-world applications that demonstrate its capabilities. High-profile infrastructure projects have successfully utilized FRP materials, from bridge reinforcements to entire pedestrian walkways, showcasing the material's versatility and reliability. The customization potential of FRP is another key characteristic that fulfills specific project requirements. These materials can be molded into complex shapes and sizes, providing bespoke solutions that meet precise engineering demands. This adaptability means architects have greater freedom in design, enabling the creation of structures that are not only functional but also aesthetically appealing. Despite the initial higher cost associated with FRP materials, lifecycle cost analysis often proves FRP sections to be more economical in the long run. The long-term reduction in maintenance, repair frequency, and associated downtime ultimately provides significant savings. Suppliers and manufacturers have been pushed to innovate further, offering advanced FRP blends and production techniques that enhance performance attributes. Ongoing research and development in the realm of fiber reinforcement and resin technology are expected to continue broadening the possibilities of FRP structural sections. For engineers and decision-makers seeking materials optimized for modern construction challenges, FRP emerges as a compelling choice. It represents the intersection of advanced material science and practical application, producing outcomes that satisfy both performance standards and economic considerations. As awareness and understanding of FRP's advantages grow, its usage is set to expand, heralding a new era in construction and infrastructure development.

The implementation of FRP sections in structural engineering has been supported by a growing body of research and case studies. Structural engineers and architects are increasingly gaining confidence in FRP due to rigorous testing and real-world applications that demonstrate its capabilities. High-profile infrastructure projects have successfully utilized FRP materials, from bridge reinforcements to entire pedestrian walkways, showcasing the material's versatility and reliability. The customization potential of FRP is another key characteristic that fulfills specific project requirements. These materials can be molded into complex shapes and sizes, providing bespoke solutions that meet precise engineering demands. This adaptability means architects have greater freedom in design, enabling the creation of structures that are not only functional but also aesthetically appealing. Despite the initial higher cost associated with FRP materials, lifecycle cost analysis often proves FRP sections to be more economical in the long run. The long-term reduction in maintenance, repair frequency, and associated downtime ultimately provides significant savings. Suppliers and manufacturers have been pushed to innovate further, offering advanced FRP blends and production techniques that enhance performance attributes. Ongoing research and development in the realm of fiber reinforcement and resin technology are expected to continue broadening the possibilities of FRP structural sections. For engineers and decision-makers seeking materials optimized for modern construction challenges, FRP emerges as a compelling choice. It represents the intersection of advanced material science and practical application, producing outcomes that satisfy both performance standards and economic considerations. As awareness and understanding of FRP's advantages grow, its usage is set to expand, heralding a new era in construction and infrastructure development.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024