loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

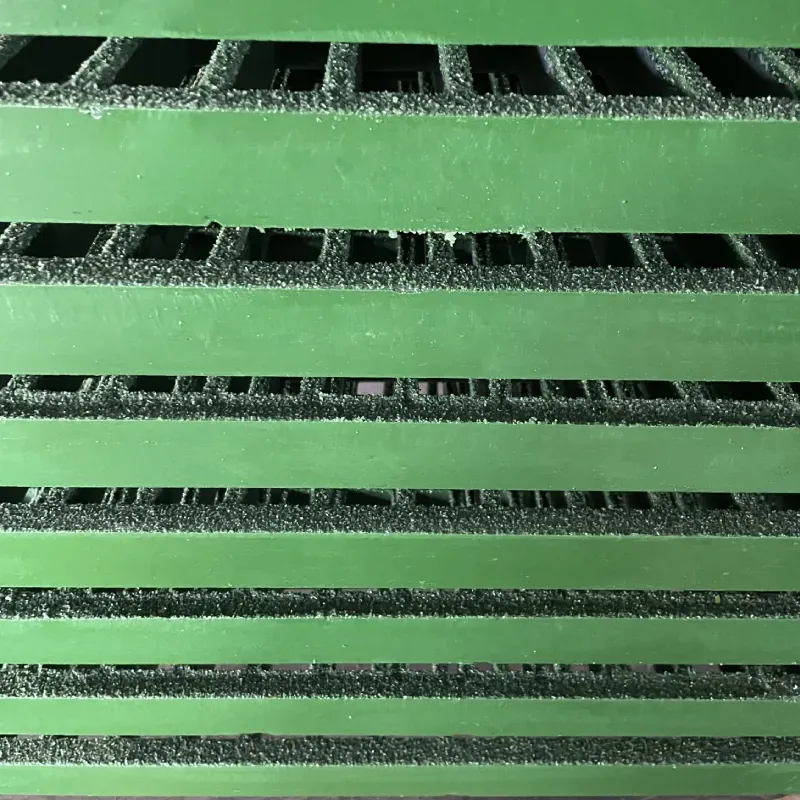

frp structural shapes

Exploring FRP Structural Shapes Innovations in Construction

Fiber Reinforced Polymer (FRP) has emerged as a revolutionary material in the field of construction and civil engineering. As industries continually seek ways to enhance structural integrity while minimizing weight and increasing durability, FRP structural shapes have become increasingly popular. These innovative materials offer numerous advantages over traditional construction materials like steel and concrete.

Exploring FRP Structural Shapes Innovations in Construction

One of the standout characteristics of FRP is its inherent resistance to corrosion. Traditional materials like steel are susceptible to rust and deterioration when exposed to moisture and environmental elements. This leads to increased maintenance costs and shortened service life in structures. On the other hand, FRP shapes can withstand harsh conditions, making them ideal for use in coastal areas, chemical plants, and other environments where corrosive substances are prevalent. This longevity translates to lower lifecycle costs and greater reliability.

frp structural shapes

In addition to corrosion resistance, FRP also offers excellent impact resistance and resilience against fatigue, making it well-suited for demanding applications. The adaptability of FRP allows engineers to create custom shapes and sizes tailored to specific project requirements. Unlike steel, which has fixed dimensions and properties, FRP can be manufactured to meet diverse design needs, enhancing architectural flexibility.

Moreover, the use of FRP structural shapes contributes positively to sustainability goals. Lightweight materials require less energy to transport and install, reducing the carbon footprint associated with construction projects. Additionally, FRP’s longevity means that structures can remain in service longer without the need for replacement, further conserving resources.

Safety is another critical consideration in modern construction, and FRP shapes provide advantages in this area as well. The non-conductive properties of FRP make it safer for use in electrical applications. Its lightweight nature also simplifies the construction process, as cranes and heavy machinery can be minimized, reducing the risk of accidents on site.

In summary, FRP structural shapes represent a significant advancement in construction materials, offering an array of benefits, including lightweight strength, corrosion resistance, design flexibility, sustainability, and improved safety. As technology continues to evolve, the integration of FRP into structural design will likely expand, paving the way for more efficient, durable, and innovative construction practices. With ongoing research and development, the future of FRP in construction promises not only to enhance the performance of structures but also to contribute positively to environmental sustainability.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024