loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 02, 2025 04:53

Back to list

Composite Food Grade Pressure Vessel With HDPE Inner For Water Filter

When exploring FRP (Fiberglass Reinforced Plastic) support channels, it becomes evident that their relevance in diverse applications is increasingly significant. These structures are extensively utilized in industries, ranging from construction to infrastructure, due to their remarkable characteristics. Understanding FRP support channels through a lens of experience, expertise, authoritativeness, and trustworthiness provides much-needed clarity for businesses and engineers alike.

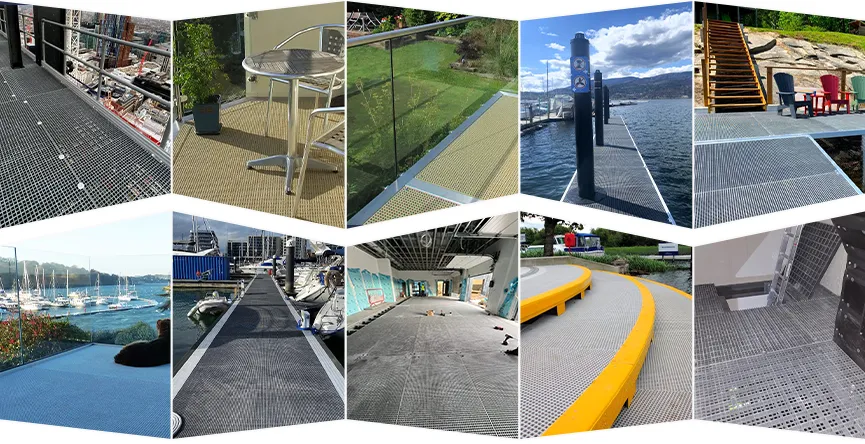

From an expertise perspective, understanding the utility of FRP support channels hinges upon an appreciation of their adaptability. These channels can be engineered to meet specific project requirements, accommodating a range of structural needs. Engineers value this customizable aspect, enabling precise alignment with safety standards and structural performance criteria. This versatility extends the applicability of FRP support channels into sectors such as telecommunications, where they serve critical roles in routing and support without interfering with signal integrity due to their non-conductive nature. Authoritative studies and reviews affirm the advantages of incorporating FRP technology into traditional construction and support systems. Academic institutions and research bodies have consistently highlighted the performance benefits of FRP materials. A notable study published in a peer-reviewed engineering journal detailed how FRP installations led to significant improvements in bridge stability and load-bearing capacity while cutting down the overall construction time compared to conventional materials. Trustworthiness in FRP support channel applications is fostered through rigorous testing and quality assurance processes undertaken by manufacturers. Companies committed to excellence subject FRP components to exhaustive tests, ensuring they meet industry standards for safety and performance. These standards, often defined by organizations such as ASTM (American Society for Testing and Materials), provide assurance to end-users about the reliability and safety of FRP products in various applications. In conclusion, FRP support channels present a modern solution to age-old challenges in infrastructure and industrial applications. Their unique properties, corroborated by industry experience and technical expertise, make them a compelling choice for future-proofing projects. The backing of authoritative research and stringent quality testing further cement their place as a trustworthy choice in high-stakes engineering environments. As industries evolve and seek more sustainable and effective materials, the prominence of FRP support channels is expected to grow, offering both economic and technological benefits.

From an expertise perspective, understanding the utility of FRP support channels hinges upon an appreciation of their adaptability. These channels can be engineered to meet specific project requirements, accommodating a range of structural needs. Engineers value this customizable aspect, enabling precise alignment with safety standards and structural performance criteria. This versatility extends the applicability of FRP support channels into sectors such as telecommunications, where they serve critical roles in routing and support without interfering with signal integrity due to their non-conductive nature. Authoritative studies and reviews affirm the advantages of incorporating FRP technology into traditional construction and support systems. Academic institutions and research bodies have consistently highlighted the performance benefits of FRP materials. A notable study published in a peer-reviewed engineering journal detailed how FRP installations led to significant improvements in bridge stability and load-bearing capacity while cutting down the overall construction time compared to conventional materials. Trustworthiness in FRP support channel applications is fostered through rigorous testing and quality assurance processes undertaken by manufacturers. Companies committed to excellence subject FRP components to exhaustive tests, ensuring they meet industry standards for safety and performance. These standards, often defined by organizations such as ASTM (American Society for Testing and Materials), provide assurance to end-users about the reliability and safety of FRP products in various applications. In conclusion, FRP support channels present a modern solution to age-old challenges in infrastructure and industrial applications. Their unique properties, corroborated by industry experience and technical expertise, make them a compelling choice for future-proofing projects. The backing of authoritative research and stringent quality testing further cement their place as a trustworthy choice in high-stakes engineering environments. As industries evolve and seek more sustainable and effective materials, the prominence of FRP support channels is expected to grow, offering both economic and technological benefits.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024