loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

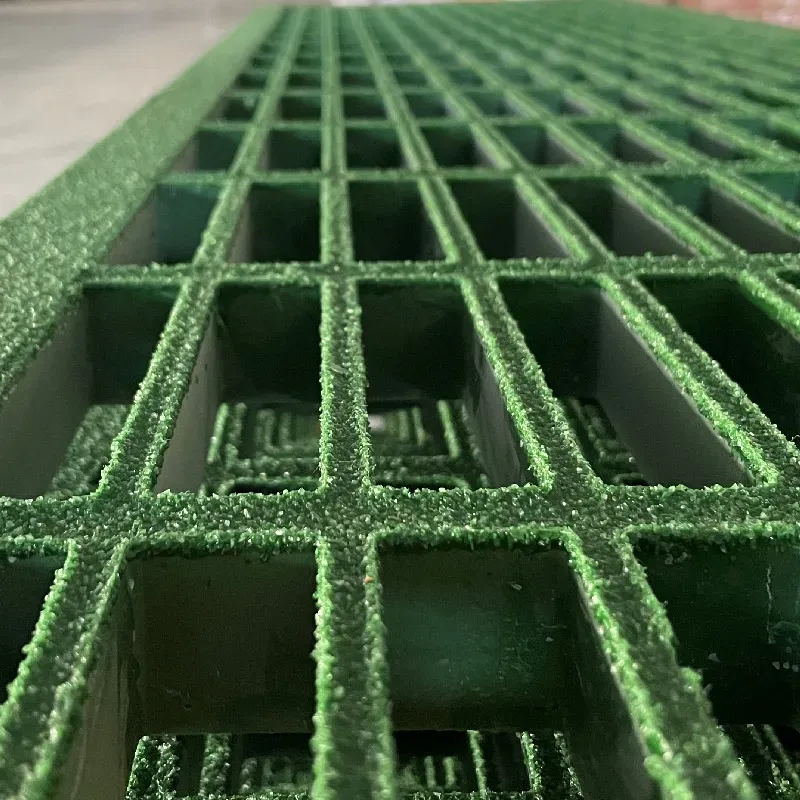

frp trench drain

The Importance of FRP Trench Drains in Modern Construction

In today's construction industry, maintaining effective drainage systems is essential to ensure the longevity and stability of infrastructure. Among the various materials and designs available, Fiber Reinforced Polymer (FRP) trench drains have emerged as a reliable choice. These trench drains combine strength, durability, and lightweight properties, making them suitable for a wide range of applications.

Advantages of FRP Trench Drains

One of the primary advantages of FRP trench drains is their resistance to corrosion. Traditional materials, such as metal and concrete, can deteriorate over time when exposed to water and various chemicals. On the other hand, FRP is intrinsically resistant to a variety of harsh elements, including acidic and caustic chemicals, making it ideal for use in industrial environments.

Additionally, FRP trench drains are lightweight yet strong. This characteristic simplifies the installation process, as they require less labor and equipment to set up compared to heavier alternatives. The reduced weight also minimizes the stress on the ground beneath, which is especially beneficial in locations with unstable soil conditions.

Another notable benefit of FRP trench drains is their versatility. They can be manufactured in various shapes and sizes to fit specific project requirements. This customization allows designers and engineers to create efficient drainage solutions tailored to the unique demands of different environments, from parking lots to chemical processing facilities.

Environmental Considerations

In an era where sustainability is a growing concern, FRP materials provide an environmentally friendly alternative. The production process of fiber reinforced polymers generates fewer greenhouse gas emissions compared to traditional concrete and metal. Moreover, FRP trench drains can often be recycled, contributing to a more sustainable construction lifecycle.

frp trench drain

Applications of FRP Trench Drains

FRP trench drains find applications across diverse sectors. In the manufacturing and food processing industries, where hygiene and cleanliness are paramount, FRP drains can handle heavy wash-down activities without the risk of corrosion or contamination. Similarly, in municipal settings, FRP trench drains can effectively manage stormwater runoff, helping to prevent flooding and erosion.

Because FRP is non-conductive, these trench drains are also suitable for electrical and telecommunications facilities. They can protect sensitive equipment from moisture while facilitating necessary drainage, thus ensuring operational continuity.

Installation and Maintenance

The installation of FRP trench drains typically follows straightforward procedures. The lightweight nature of FRP materials allows for easier transport and placement, reducing overall project timelines. Furthermore, once installed, FRP trench drains require minimal maintenance. Regular cleaning and inspection are usually sufficient to keep the system functioning optimally, thanks to the smooth surface that reduces the buildup of debris and sediments.

Conclusion

In summary, FRP trench drains represent a significant advancement in drainage technology. Their resistance to corrosion, lightweight design, and versatility make them an excellent choice for various applications in modern construction. By considering the environmental impact and ease of maintenance associated with FRP materials, engineers and builders can make informed decisions that promote both functionality and sustainability in their projects. As we continue to evolve in building practices, FRP trench drains will undoubtedly play a pivotal role in shaping the future of infrastructure development.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024