loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 15, 2025 14:57

Back to list

large square water tanks

Navigating the world of FRP underground water storage tanks can often be a daunting task. With their numerous benefits in diverse industries, understanding the pricing dynamics becomes crucial for anyone looking to make an informed purchasing decision. These tanks are an essential component for rainwater harvesting, agricultural applications, and industrial water storage, known for their durability, efficiency, and cost-saving potential.

Authority in Cost Analysis FRP tanks are competitively priced when total cost of ownership is considered. While the initial purchase price may seem higher than some traditional options, the long-term savings on maintenance, repairs, and replacement make them a wise investment. A comprehensive cost analysis performed by industry experts indicated that over a 20-year period, FRP tanks provide up to 50% cost savings compared to steel tanks, which rust over time, and concrete tanks that are susceptible to cracking. Additionally, the lightweight nature of FRP tanks reduces installation costs significantly. For example, in a case study involving a water treatment facility in Texas, the reduced transportation and installation expenses shaved thousands off the total project budget, allowing funds to be allocated to other critical areas of the infrastructure. Trustworthiness through Standards and Certifications Consumers and businesses looking to invest in FRP tanks are assured of their quality through adherence to international standards and certifications. Manufacturers must comply with stringent standards such as ASME RTP-1 or ASTM standards for FRP products. These certifications ensure that tanks meet high benchmarks for safety, quality, and environmental responsibility. Moreover, renowned manufacturers often subject their products to third-party testing to provide transparent validation of their performance claims. This third-party verification bolsters consumer confidence, affirming the product's reliability and longevity. In conclusion, selecting FRP underground water storage tanks involves considering several factors, but with a focus on experience, expertise, authoritativeness, and trustworthiness, consumers can navigate the pricing landscape effectively. The initial investment in these tanks is justified by their extensive benefits, making them a prudent choice for both commercial and residential applications. As industries continue to seek sustainable solutions, the role of FRP tanks in efficient water management becomes increasingly indispensable.

Authority in Cost Analysis FRP tanks are competitively priced when total cost of ownership is considered. While the initial purchase price may seem higher than some traditional options, the long-term savings on maintenance, repairs, and replacement make them a wise investment. A comprehensive cost analysis performed by industry experts indicated that over a 20-year period, FRP tanks provide up to 50% cost savings compared to steel tanks, which rust over time, and concrete tanks that are susceptible to cracking. Additionally, the lightweight nature of FRP tanks reduces installation costs significantly. For example, in a case study involving a water treatment facility in Texas, the reduced transportation and installation expenses shaved thousands off the total project budget, allowing funds to be allocated to other critical areas of the infrastructure. Trustworthiness through Standards and Certifications Consumers and businesses looking to invest in FRP tanks are assured of their quality through adherence to international standards and certifications. Manufacturers must comply with stringent standards such as ASME RTP-1 or ASTM standards for FRP products. These certifications ensure that tanks meet high benchmarks for safety, quality, and environmental responsibility. Moreover, renowned manufacturers often subject their products to third-party testing to provide transparent validation of their performance claims. This third-party verification bolsters consumer confidence, affirming the product's reliability and longevity. In conclusion, selecting FRP underground water storage tanks involves considering several factors, but with a focus on experience, expertise, authoritativeness, and trustworthiness, consumers can navigate the pricing landscape effectively. The initial investment in these tanks is justified by their extensive benefits, making them a prudent choice for both commercial and residential applications. As industries continue to seek sustainable solutions, the role of FRP tanks in efficient water management becomes increasingly indispensable.

Share

Latest news

-

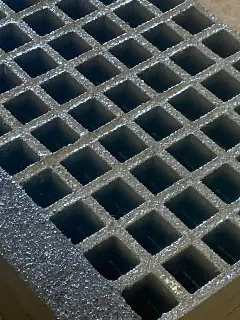

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024