loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp vessel 1865

Exploring the FRP Vessel of 1865 Innovations in Marine Engineering

The year 1865 marked a significant milestone in marine engineering with the introduction of Fiber Reinforced Plastic (FRP) vessels. This innovative material revolutionized boat design and construction, offering superior durability, lightweight characteristics, and resistance to corrosion compared to traditional materials such as wood, steel, or iron. The development of FRP technology not only transformed vessel manufacturing but also influenced various industries that depend on maritime transport.

Historically, the marine industry relied heavily on wooden ships and iron hulls. While these materials were effective, they had several limitations. Wooden ships, for instance, required extensive maintenance due to rot and pest damage. Iron vessels, although durable, were susceptible to rust and heavy, significantly impacting speed and fuel efficiency. The search for a more reliable alternative led to the exploration of composite materials, culminating in the birth of FRP vessels.

Exploring the FRP Vessel of 1865 Innovations in Marine Engineering

One of the most noteworthy features of the FRP vessel is its reduced weight, which allows for increased cargo capacity and improved fuel efficiency. With lighter ships, operators could engage in longer voyages without the need for frequent refueling, thus enhancing overall operational efficiency. This aspect became increasingly important as commercial shipping expanded in the late 19th century, necessitating ships that could travel longer distances at a lower cost.

frp vessel 1865

Moreover, the corrosion resistance of FRP materials played a crucial role in extending a vessel's lifespan. Traditional materials often succumbed to the relentless effects of seawater, requiring costly repairs and maintenance. In contrast, FRP vessels significantly minimized these issues, leading to lower lifecycle costs and increased profitability for shipping companies. By the late 1800s, the adoption of FRP technology continued to gain traction, as builders recognized the economic advantages and performance benefits it provided.

The introduction of FRP vessels also opened new avenues for design and engineering. With the ability to mold complex shapes and structures, engineers could create innovative hull designs, improving hydrodynamics and enhancing vessel performance. This flexibility in design allowed for the development of a wide range of vessel types, from small recreational boats to large cargo ships, each tailored to specific operational needs.

In addition to commercial applications, FRP technology found its way into military and research vessels. The United States Navy, recognizing the advantages of this material, began to explore its applications in shipbuilding during the late 1960s. Similarly, research organizations harnessed the lightweight and durable properties of FRP for oceanographic and environmental studies, enabling deeper explorations and more effective research missions.

As we reflect on the contributions of the 1865 FRP vessel, it is clear that this innovation was not merely a technological advancement; it represented a paradigm shift in the maritime industry. The integration of composite materials into vessel design has set the stage for ongoing innovation, leading to the modern ships that navigate our oceans today.

In conclusion, the introduction of FRP vessels in 1865 showcases the impact of material science and engineering in shaping the future of marine transport. By addressing the shortcomings of existing materials, this innovation paved the way for more efficient, durable, and versatile vessel designs. As the maritime industry continues to evolve, the legacy of FRP technology endures, underscoring its significance in the ongoing quest for greater efficiency and sustainability in marine engineering.

-

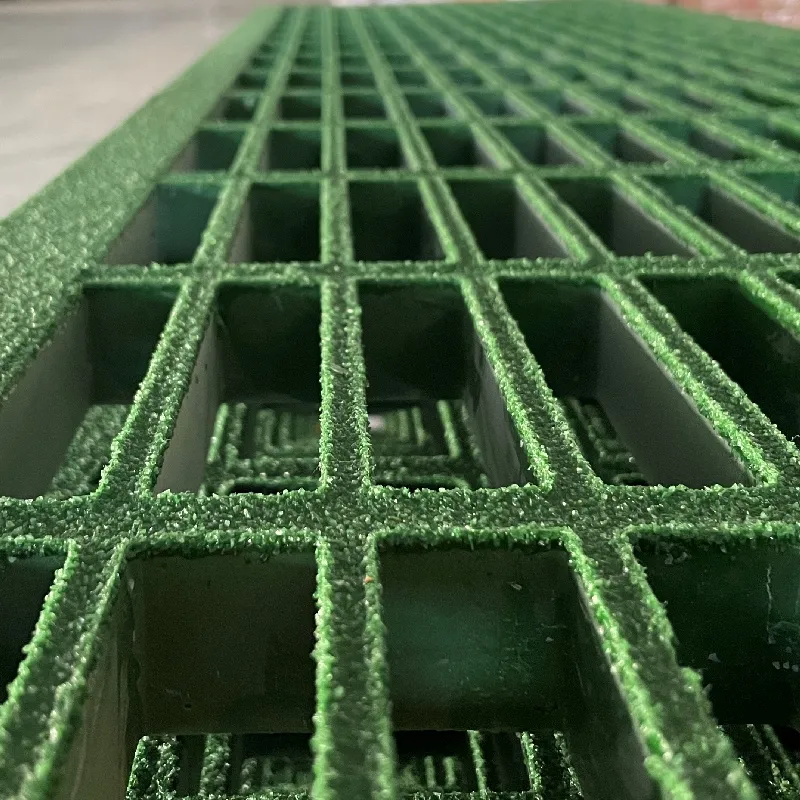

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024