loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 15, 2025 03:30

Back to list

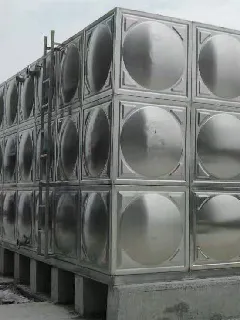

frp vessel for water treatment

FRP (Fiber Reinforced Plastic) vessels, particularly the model identified as FRP vessel 1865, have increasingly become a focal point for industries seeking superior, reliable, and durable storage solutions. These vessels are crafted to meet high standards of safety and efficiency, embodying profound expertise across their production to application.

Authoritative use of FRP vessel 1865 is evident from endorsements by industry leaders and specialists who recognize the vessel's compliance with international safety standards. Consistent innovation and manufacturing precision are key facets that contribute to its authoritative status within various sectors. Industry experts and engineers stand behind the vessel's performance data, offering substantial validation through stress tests and environmental assessments. Trustworthiness is an essential component of FRP vessel 1865's reputation. Users have consistently reported remarkable satisfaction with not only the product's functionality but also the customer service backing the purchase. Manufacturers of these vessels prioritize transparency and openness by providing comprehensive documentation and support, which in turn bolsters user confidence in the product's long-term viability and reliability. Choosing an FRP vessel such as the model 1865 involves understanding specific operational needs. Technical specifications suggest a design catering to high-capacity storage, suitable for bulk processing plants and dispatch facilities. Considering geographical location and environmental exposure are also pivotal in selecting the appropriate vessel configuration and coatings. In conclusion, the FRP vessel 1865 represents cutting-edge development in the field of storage and processing containers. Its fusion of durability and chemical resistance, backed by expert manufacturing and authoritative use, positions it as a leading choice for industries demanding reliable and cost-effective solutions. Trust in its performance is continually reinforced through positive industry experiences and a strong foundation of professional expertise, solidifying its place in the future landscape of industrial storage technology.

Authoritative use of FRP vessel 1865 is evident from endorsements by industry leaders and specialists who recognize the vessel's compliance with international safety standards. Consistent innovation and manufacturing precision are key facets that contribute to its authoritative status within various sectors. Industry experts and engineers stand behind the vessel's performance data, offering substantial validation through stress tests and environmental assessments. Trustworthiness is an essential component of FRP vessel 1865's reputation. Users have consistently reported remarkable satisfaction with not only the product's functionality but also the customer service backing the purchase. Manufacturers of these vessels prioritize transparency and openness by providing comprehensive documentation and support, which in turn bolsters user confidence in the product's long-term viability and reliability. Choosing an FRP vessel such as the model 1865 involves understanding specific operational needs. Technical specifications suggest a design catering to high-capacity storage, suitable for bulk processing plants and dispatch facilities. Considering geographical location and environmental exposure are also pivotal in selecting the appropriate vessel configuration and coatings. In conclusion, the FRP vessel 1865 represents cutting-edge development in the field of storage and processing containers. Its fusion of durability and chemical resistance, backed by expert manufacturing and authoritative use, positions it as a leading choice for industries demanding reliable and cost-effective solutions. Trust in its performance is continually reinforced through positive industry experiences and a strong foundation of professional expertise, solidifying its place in the future landscape of industrial storage technology.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024