loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

FRP Tanks for Efficient Water Treatment Solutions and Their Applications

FRP Vessels for Water Treatment A Sustainable Solution

Water treatment is a critical component of maintaining public health and safeguarding the environment. Traditional methods, often relying on steel or concrete vessels, can pose challenges regarding durability, weight, and corrosion resistance. In recent years, Fiber Reinforced Plastic (FRP) vessels have emerged as a sustainable and efficient alternative, offering numerous benefits that make them increasingly popular in the water treatment industry.

Understanding FRP

Fiber Reinforced Plastic is a composite material made of a polymer matrix reinforced with fibers, usually glass, carbon, or aramid. This combination results in a lightweight yet strong structure, making FRP vessels particularly advantageous for various applications, including water treatment. The unique properties of FRP—such as resistance to corrosion, ease of installation, and low maintenance—have made it an ideal choice for water treatment facilities.

Advantages of FRP Vessels

1. Corrosion Resistance Water treatment often involves harsh chemicals and varying pH levels, which can lead to corrosion in traditional materials. FRP vessels are inherently resistant to chemical damage, ensuring their longevity and reliability in treating water without the risk of material degradation.

2. Lightweight and Easy to Install One of the standout features of FRP is its lightweight nature. This characteristic reduces transportation costs and makes installation easier, allowing for quicker setup times at treatment facilities. The reduced weight also diminishes the structural requirements for foundations and supports, leading to overall cost savings in construction and maintenance.

3. Customizable Designs FRP technology allows for customization in design and capacity, accommodating the specific needs of different water treatment systems. Whether dealing with potable water, wastewater, or industrial effluents, FRP vessels can be tailored for optimal efficiency and effectiveness, fulfilling various operational requirements.

4. Enhanced Thermal and Electrical Insulation FRP materials provide excellent thermal and electrical insulation, which is crucial in maintaining consistent operating temperatures and enhancing safety during the water treatment process. This insulation capability helps in reducing energy consumption, contributing further to the sustainability of the facilities.

frp vessel for water treatment

5. Lower Maintenance Costs The durability and resistance of FRP to environmental factors mean less frequent repairs and replacements compared to traditional materials. This lower maintenance requirement results in significant cost savings over the lifespan of the vessel, making it a financially sound investment for water treatment facilities.

Environmental Impact

Adopting FRP vessels in water treatment presents an opportunity to advance sustainability efforts. The longevity of these vessels means less frequent replacements, reducing material waste. Furthermore, FRP’s manufacturing process can be optimized to use fewer resources, and when disposed of, FRP can often be recycled, minimizing its environmental footprint.

Applications in Water Treatment

FRP vessels are extensively used in various applications within water treatment, including filtration, storage, and chemical dosing systems. For instance, in reverse osmosis systems, FRP membranes are employed due to their resistance against fouling and scaling, ensuring efficient operation over extended periods.

Moreover, as industries increasingly focus on sustainable practices, FRP vessels can play a vital role in meeting regulatory standards and public expectations for environmentally responsible operations.

Conclusion

In summary, FRP vessels represent a leap forward in water treatment technology. Their benefits—including corrosion resistance, lightweight construction, customization potential, and lower maintenance costs—position them as a smart choice for facilities aiming to enhance efficiency while minimizing environmental impact. As the industry continues to evolve, FRP technology will likely play an increasingly prominent role in achieving sustainable water treatment solutions. Adopting this innovative approach not only improves operational performance but also supports the global imperative for water conservation and environmental stewardship.

-

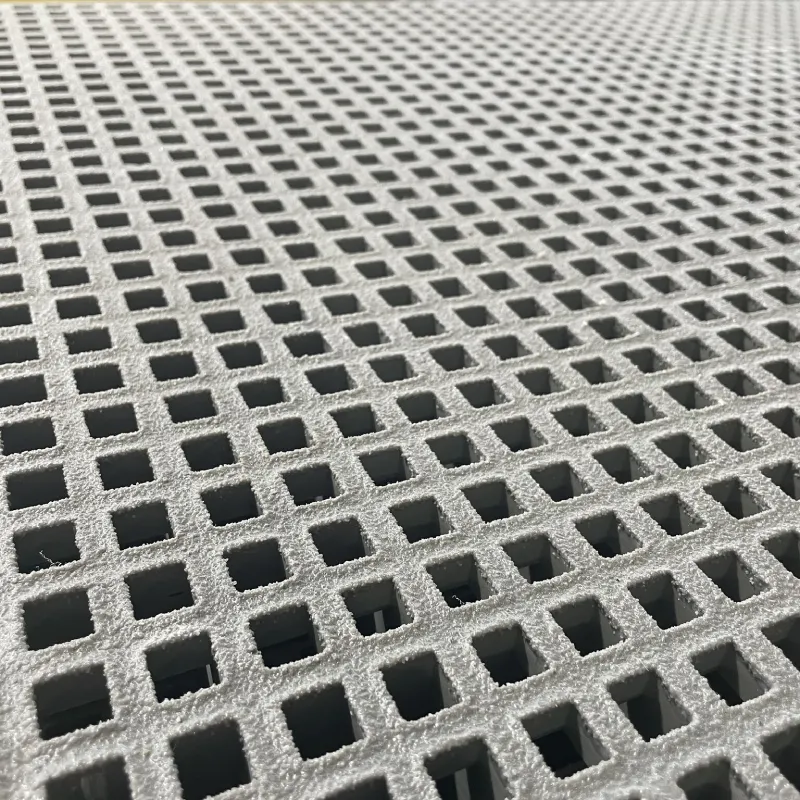

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024