loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Exploring the Benefits of Fiberglass Reinforced Plastic Vessels in Modern Applications

Understanding FRP Vessels Innovations and Applications

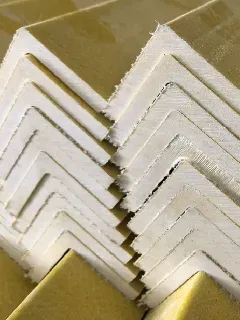

Fiber Reinforced Polymer (FRP) vessels have gained significant traction in various industries due to their advantageous properties over traditional materials such as steel and concrete. These vessels, made from composite materials that reinforce polymer resin with fibers (such as glass, carbon, or aramid), offer a unique combination of strength, lightweight characteristics, and corrosion resistance. As industries seek to enhance performance while reducing costs, FRP vessels have emerged as a vital solution.

Advantages of FRP Vessels

One of the primary advantages of FRP vessels is their exceptional strength-to-weight ratio. Traditional material vessels can be cumbersome and heavy, which poses challenges for transport and installation. In contrast, FRP vessels are lightweight, making them easier to handle and install. This characteristic is particularly beneficial in applications such as marine, chemical processing, and oil and gas sectors, where reducing weight can significantly lower transportation costs and facilitate installation on sites with accessibility constraints.

Moreover, FRP vessels exhibit superior resistance to corrosion and chemical abrasion compared to conventional materials. This resistance extends the lifespan of vessels used in harsh environments, such as wastewater treatment plants, where exposure to corrosive substances is common. The longevity of FRP vessels leads to reduced maintenance costs and downtime, providing a more economical solution over time.

Design Flexibility and Customization

Another compelling feature of FRP vessels is design flexibility. The manufacturing process of FRP composites allows for a variety of shapes and sizes to accommodate specific operational requirements. This flexibility makes it possible to create tailored solutions for diverse industrial applications, from storage tanks to pressure vessels. Customization options also include varying fiber types and orientations, enabling engineers to optimize the mechanical properties of the vessel for a given application.

Applications in Various Industries

frp vessels

FRP vessels are utilized across various sectors, including water treatment, chemical storage, oil and gas, and renewable energy. In water and wastewater treatment, they serve as tanks for storage and processing, effectively eliminating problems associated with corrosion and extending service life. In the chemical industry, FRP vessels are ideal for storing corrosive substances due to their chemical resistance, providing safety and reliability in operations.

In the oil and gas sector, FRP vessels are increasingly replacing traditional materials for applications like separators, storage tanks, and pipeline systems. Their lightweight nature allows for easier installation, while their corrosion resistance minimizes the risks of leaks and environmental damage. The renewable energy sector also benefits from FRP materials, particularly in the construction of wind turbine blades, where lightweight and durability are critical for efficiency.

Challenges and Considerations

Despite the numerous advantages, the adoption of FRP vessels is not without challenges. The initial cost of FRP is often higher than that of traditional materials, which can deter some industries from making the switch. Moreover, the manufacturing process requires specialized expertise, and issues related to the consistent quality of the composites can arise if not properly managed.

Furthermore, while FRP materials are resistant to many chemicals, they are not universally applicable. It is crucial for engineers to consider the specific operating environment and conditions when selecting materials, as some chemicals can degrade certain types of polymers.

Conclusion

In summary, FRP vessels represent a significant advancement in material technology, offering numerous benefits such as lightweight design, corrosion resistance, and flexibility in engineering solutions. As industries increasingly prioritize safety, efficiency, and sustainability, the demand for FRP vessels is likely to grow. Although challenges remain in terms of cost and material compatibility, the potential for improved performance and durability makes FRP an attractive option for future industrial applications. As innovations in material science continue, FRP vessels will undoubtedly play a crucial role in shaping the future of various sectors.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024