loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1 月 . 15, 2025 09:49

Back to list

Composite Food Grade Pressure Vessel With HDPE Inner For Water Filter

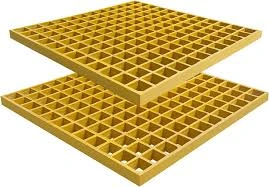

FRP walkways are redefining the landscape of industrial infrastructure by offering a safer, more durable, and cost-effective alternative to traditional materials like wood, steel, and aluminum. Drawing from years of industry experience, it’s clear that FRP (Fiberglass Reinforced Plastic) is not just a trend, but a revolution in walkway solutions.

Product-wise, FRP walkways offer unparalleled versatility in design. They can be customized to fit any space, whether it’s a rooftop needing lightweight materials or a factory floor requiring heavy-duty grating. Installation is straightforward, often requiring no heavy machinery, which speeds up deployment and reduces associated costs. Moreover, the modularity of FRP systems allows for quick adjustments and expansions, giving businesses the flexibility to adapt to changing operational needs. Environmental impact is another crucial factor where FRP walkways excel. The production process of FRP materials is less energy-intensive compared to metal fabrication, contributing to a lower carbon footprint. Furthermore, FRP walkways do not require harmful chemical treatments used to preserve wood or keep steel from rusting, offering a cleaner, more sustainable solution. User testimonials accentuate the practical benefits of these walkways. Operators report improved workplace safety due to reduced slipperiness, even when wet, and enhanced thermal properties minimize heat transfer, making surfaces more comfortable to walk on in extreme temperatures. In conclusion, FRP walkways represent a holistic improvement in infrastructure technology. They offer a compelling combination of strength, durability, safety, and environmental sustainability. As industries continue to demand solutions that are not only cost-effective but also meet stringent safety and environmental standards, FRP walkways are poised to lead the way. Whether it’s for industrial, commercial, or even residential applications, the trust and authority that come with adopting FRP solutions ensure a wise investment today and a crucial asset for the future.

Product-wise, FRP walkways offer unparalleled versatility in design. They can be customized to fit any space, whether it’s a rooftop needing lightweight materials or a factory floor requiring heavy-duty grating. Installation is straightforward, often requiring no heavy machinery, which speeds up deployment and reduces associated costs. Moreover, the modularity of FRP systems allows for quick adjustments and expansions, giving businesses the flexibility to adapt to changing operational needs. Environmental impact is another crucial factor where FRP walkways excel. The production process of FRP materials is less energy-intensive compared to metal fabrication, contributing to a lower carbon footprint. Furthermore, FRP walkways do not require harmful chemical treatments used to preserve wood or keep steel from rusting, offering a cleaner, more sustainable solution. User testimonials accentuate the practical benefits of these walkways. Operators report improved workplace safety due to reduced slipperiness, even when wet, and enhanced thermal properties minimize heat transfer, making surfaces more comfortable to walk on in extreme temperatures. In conclusion, FRP walkways represent a holistic improvement in infrastructure technology. They offer a compelling combination of strength, durability, safety, and environmental sustainability. As industries continue to demand solutions that are not only cost-effective but also meet stringent safety and environmental standards, FRP walkways are poised to lead the way. Whether it’s for industrial, commercial, or even residential applications, the trust and authority that come with adopting FRP solutions ensure a wise investment today and a crucial asset for the future.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024