loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

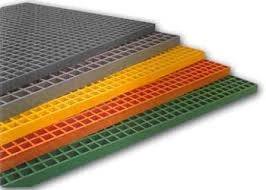

Durable FRP Walkway Grating Solutions for Safe and Efficient Foot Traffic

Exploring FRP Walkway Grating A Revolution in Industrial Flooring

Fiber Reinforced Polymer (FRP) walkway grating is transforming industrial flooring solutions, combining strength, durability, and lightweight characteristics to offer an ideal choice for various applications. This innovative material is increasingly being adopted in settings ranging from manufacturing facilities to wastewater treatment plants, providing a robust and versatile surface that meets the demands of modern infrastructure.

What is FRP Walkway Grating?

FRP walkway grating is made from a composite material that includes a polymer matrix reinforced with glass fibers. This unique composition provides exceptional strength-to-weight ratios, making it a preferred option over traditional materials like metal or wood. The manufacturing process usually involves pultrusion, a technique that draws the composite resins and fibers through a heated die to create a rigid, consistent product. The result is a grating solution capable of withstanding heavy loads while remaining lightweight and easy to handle.

Advantages of FRP Walkway Grating

One of the main benefits of FRP walkway grating is its corrosion resistance. Unlike metal grating, which can rust or degrade when exposed to harsh chemicals or environmental conditions, FRP is impervious to corrosion. This feature makes it particularly suitable for applications in chemical plants, marine environments, and other settings where exposure to corrosive substances is a concern.

Another significant advantage is the non-slip surface provided by FRP grating. Many FRP products are designed with a textured surface that enhances traction, reducing the risk of slips and falls, particularly in wet or oily conditions. This safety feature is critical in industrial workplaces, where maintaining a secure footing is essential to prevent accidents.

FRP walkway grating is also easy to install and maintain. Its lightweight nature allows for quick handling and installation, which can save both time and labor costs on projects. Additionally, the grating requires minimal maintenance; its resistance to wear and degradation means that it will not need frequent replacements, contributing to lower life-cycle costs.

frp walkway grating

Environmental Benefits

In an era where sustainability is a key concern, FRP grating stands out for its environmentally friendly properties. The production of FRP uses fewer resources compared to traditional materials, and many FRP products can be recycled. Moreover, their longevity and resistance to environmental damage mean that less material ends up in landfills over time.

Applications of FRP Walkway Grating

The versatility of FRP walkway grating is evident in its wide range of applications. It is commonly used in industrial settings, such as factories, chemical plants, and oil refineries, where safety and durability are paramount. It is also popular in the construction of pedestrian walkways, bridges, and platforms in recreational areas and parks.

Additionally, FRP grating is increasingly being utilized in municipal projects, such as drainage covers and access platforms in wastewater treatment facilities. Its resistance to chemicals and easy clean-up capabilities make it an ideal choice for environments where hygiene and safety are critical.

Conclusion

In conclusion, FRP walkway grating represents a significant advancement in industrial flooring technology. Its unique combination of strength, corrosion resistance, and non-slip properties makes it an optimal choice for various applications. As businesses continue to prioritize safety, sustainability, and efficiency, FRP walkway grating is poised to play a crucial role in shaping the future of industrial flooring solutions. By choosing FRP, industries not only enhance their operational safety but also contribute to a more sustainable future. The revolution in walkway grating is here, and it's made of fiber-reinforced polymer.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024