loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1 月 . 20, 2025 00:29

Back to list

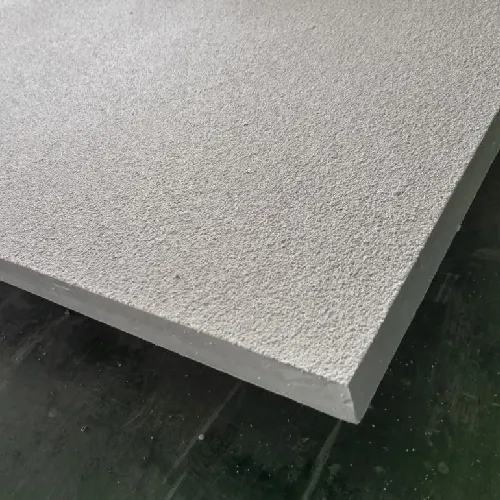

galvanised floor grating

Galvanized floor grating stands out as a crucial component in various industrial and commercial settings due to its exceptional durability, safety, and versatility. As a seasoned expert in the field, sharing insights into the intricate details of this product showcases not only the experience gathered over years but also underscores the professional prowess required to navigate its applications effectively.

Trustworthiness is paramount when sourcing galvanized grating products. Collaborating with manufacturers known for consistent quality and adherence to industry standards ensures that every piece of grating installed will perform as expected. Trust also extends to the information provided about these products, ensuring potential users are informed about installation techniques, load capacities, and maintenance requirements. Transparent communication regarding these factors builds trust and fosters long-term relationships with clients. In the dynamic landscape of industrial flooring solutions, staying informed about technological advancements in galvanization methods and grating design is essential. Innovative methods such as hot-dip galvanizing offer increased protection layers, while precision engineering can deliver customized grating solutions that fit specific project requirements. Ultimately, the journey of exploring galvanized floor grating is an intersection of experience, expertise, authority, and trust. From understanding the galvanization process to selecting the right type of grating and ensuring quality sourcing, these elements form a holistic approach to optimizing industrial settings. By prioritizing these attributes, businesses can enhance operational efficiency, safeguard personnel, and invest in solutions that deliver long-term value. Whether one needs a robust platform for manufacturing operations or reliable walkways for public spaces, galvanized floor grating offers an exemplary solution, versatile enough to meet diverse needs. Its integration into a structural framework goes beyond mere functionality, embodying principles of durability, safety, and strategic planning. Engaging with the nuances of this product empowers stakeholders to make informed decisions, yielding solutions that not only meet immediate requirements but also adapt to future challenges successfully.

Trustworthiness is paramount when sourcing galvanized grating products. Collaborating with manufacturers known for consistent quality and adherence to industry standards ensures that every piece of grating installed will perform as expected. Trust also extends to the information provided about these products, ensuring potential users are informed about installation techniques, load capacities, and maintenance requirements. Transparent communication regarding these factors builds trust and fosters long-term relationships with clients. In the dynamic landscape of industrial flooring solutions, staying informed about technological advancements in galvanization methods and grating design is essential. Innovative methods such as hot-dip galvanizing offer increased protection layers, while precision engineering can deliver customized grating solutions that fit specific project requirements. Ultimately, the journey of exploring galvanized floor grating is an intersection of experience, expertise, authority, and trust. From understanding the galvanization process to selecting the right type of grating and ensuring quality sourcing, these elements form a holistic approach to optimizing industrial settings. By prioritizing these attributes, businesses can enhance operational efficiency, safeguard personnel, and invest in solutions that deliver long-term value. Whether one needs a robust platform for manufacturing operations or reliable walkways for public spaces, galvanized floor grating offers an exemplary solution, versatile enough to meet diverse needs. Its integration into a structural framework goes beyond mere functionality, embodying principles of durability, safety, and strategic planning. Engaging with the nuances of this product empowers stakeholders to make informed decisions, yielding solutions that not only meet immediate requirements but also adapt to future challenges successfully.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024