loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

3 月 . 06, 2025 11:54

Back to list

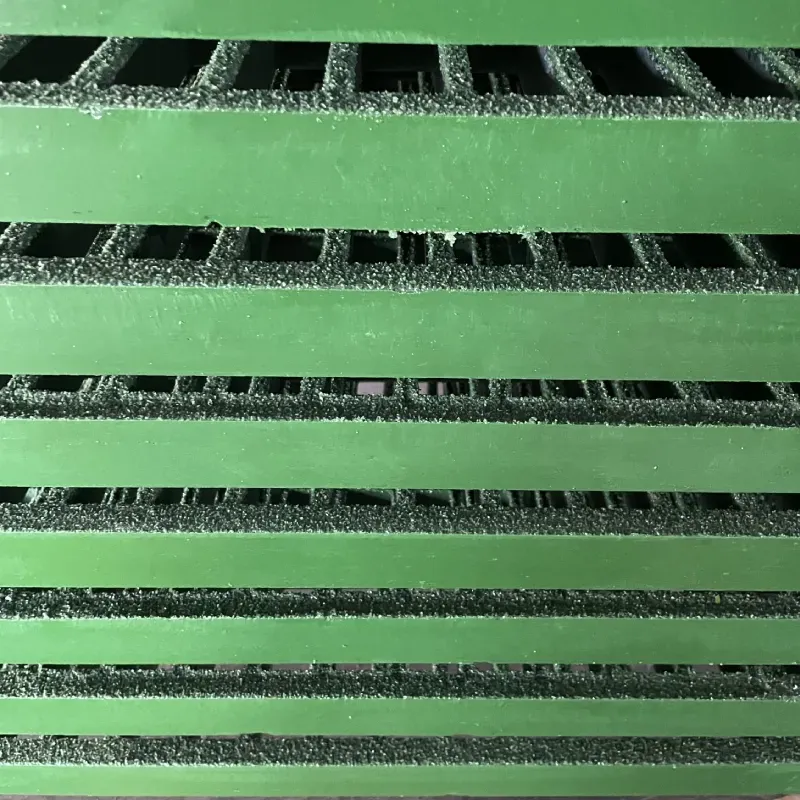

galvanised floor grating

Galvanised floor gratings represent a pivotal element in industrial and commercial environments, renowned for their robustness, safety, and longevity. Unlike traditional flooring options, galvanised gratings offer unmatched durabilities, such as exceptional resistance to corrosion and insidious environmental factors. This makes them an unparalleled choice for facilities exposed to moisture, chemicals, and heavy loads—a testimony to their strategic engineering and design.

The authoritativeness of galvanised floor grating as a choice is reflected in its widespread approval across various industry standards and regulations. Institutions and municipalities often mandate its use in public works and industrial projects, attesting to its reliability and effectiveness. For businesses committed to upholding rigorous compliance standards, investing in galvanised gratings not only meets but often exceeds the safety and operational guidelines that are critical to sustainability and trustworthiness. Trustworthiness is a cornerstone in selecting infrastructure materials, and galvanised floor grating excels in demonstrating resilience and reliability. Industries faced with harsh operational conditions frequently share success stories of grating installations that have surpassed performance expectations over decades. These instances bolster confidence in galvanised solutions as a timeless investment, offering peace of mind through unwavering structural integrity. In conclusion, choosing galvanised floor grating is an informed decision that fuses real-world experience with expert knowledge, industry authority, and indisputable trustworthiness. Facilities equipped with such gratings enjoy a harmonious blend of safety, durability, and reliability that meets the tough demands of industrial operations. As industries evolve, the galvanised floor grating remains an indispensable asset, ensuring structural excellence and operational efficiency for years to come.

The authoritativeness of galvanised floor grating as a choice is reflected in its widespread approval across various industry standards and regulations. Institutions and municipalities often mandate its use in public works and industrial projects, attesting to its reliability and effectiveness. For businesses committed to upholding rigorous compliance standards, investing in galvanised gratings not only meets but often exceeds the safety and operational guidelines that are critical to sustainability and trustworthiness. Trustworthiness is a cornerstone in selecting infrastructure materials, and galvanised floor grating excels in demonstrating resilience and reliability. Industries faced with harsh operational conditions frequently share success stories of grating installations that have surpassed performance expectations over decades. These instances bolster confidence in galvanised solutions as a timeless investment, offering peace of mind through unwavering structural integrity. In conclusion, choosing galvanised floor grating is an informed decision that fuses real-world experience with expert knowledge, industry authority, and indisputable trustworthiness. Facilities equipped with such gratings enjoy a harmonious blend of safety, durability, and reliability that meets the tough demands of industrial operations. As industries evolve, the galvanised floor grating remains an indispensable asset, ensuring structural excellence and operational efficiency for years to come.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024