loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Durable and Versatile Galvanized Steel Floor Grating for Industrial Applications

The Benefits and Applications of Galvanized Floor Grating

When it comes to industrial and commercial flooring solutions, galvanized floor grating stands out as an efficient and durable option. This type of flooring tool is engineered to provide structural support while facilitating drainage, ventilation, and safety. Galvanization is the process of applying a protective zinc coating to steel or iron to prevent rust and corrosion, thus enhancing the material's longevity and reliability. In this article, we will explore the various advantages and applications of galvanized floor grating.

Durability and Longevity

One of the primary benefits of galvanized floor grating is its extraordinary durability. The galvanization process offers a robust barrier against environmental factors. Industrial settings often expose flooring materials to moisture, chemicals, and heavy loads. Galvanized floor grating can withstand these elements without significant deterioration. It is resistant to rust and requires minimal maintenance, making it a cost-effective solution in the long run. This longevity is particularly beneficial in industries such as manufacturing, oil and gas, and wastewater management, where the flooring must endure harsh conditions.

Safety Features

Flooring safety is paramount in any industrial or commercial environment. Galvanized floor grating is designed with safety in mind. The open design of grating facilitates drainage, potentially reducing the risk of slip hazards caused by pooling water. The surface of galvanized grating can be customized with non-slip coatings or additional texturing, enhancing friction and providing increased traction. For those working at heights, the structural integrity of the grating ensures reliable load-bearing capacity, crucial for personnel safety on walkways, platforms, and production floors.

Versatility in Application

galvanized floor grating

Galvanized floor grating is incredibly versatile, making it suitable for a plethora of applications. In industrial settings, it is commonly used for walkways, platforms, stair treads, and work areas. Its lightweight yet strong composition allows for ease of installation and flexibility, facilitating efficient workflow. Additionally, the transparency of the grating allows for electrical and mechanical systems to be housed beneath, simplifying maintenance and reducing clutter.

In commercial settings, galvanized flooring can be applied in food processing facilities, where hygiene is critical. The easy-to-clean, open design prevents the accumulation of debris and spills, aligning perfectly with food safety regulations. Moreover, rust-free flooring is essential in laboratories and pharmaceutical environments where contamination risks must be minimized.

Environmental Considerations

Sustainability is a growing concern in modern industrial practices, and galvanized floor grating contributes positively to ecological considerations. The materials used in producing galvanized grating are recyclable. Once the product reaches the end of its life cycle, it can be repurposed, thus minimizing waste and conserving natural resources. Companies focusing on sustainable building practices find that using galvanized products aligns with their goals of reducing their carbon footprint.

Conclusion

In summary, galvanized floor grating represents a perfect blend of strength, safety, and sustainability, making it an ideal choice for diverse applications. The distinct features of this flooring solution provide advantages that span durability, safety, versatility, and environmental responsibility. As industries continue to evolve, the demand for reliable flooring solutions like galvanized grating will likely increase. Companies looking to enhance their workspaces should consider incorporating galvanized floor grating, as it promises long-term benefits that contribute to both productivity and safety in the workplace. Invest in galvanized floor grating today and pave the way for a secure, efficient, and enduring industrial environment.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

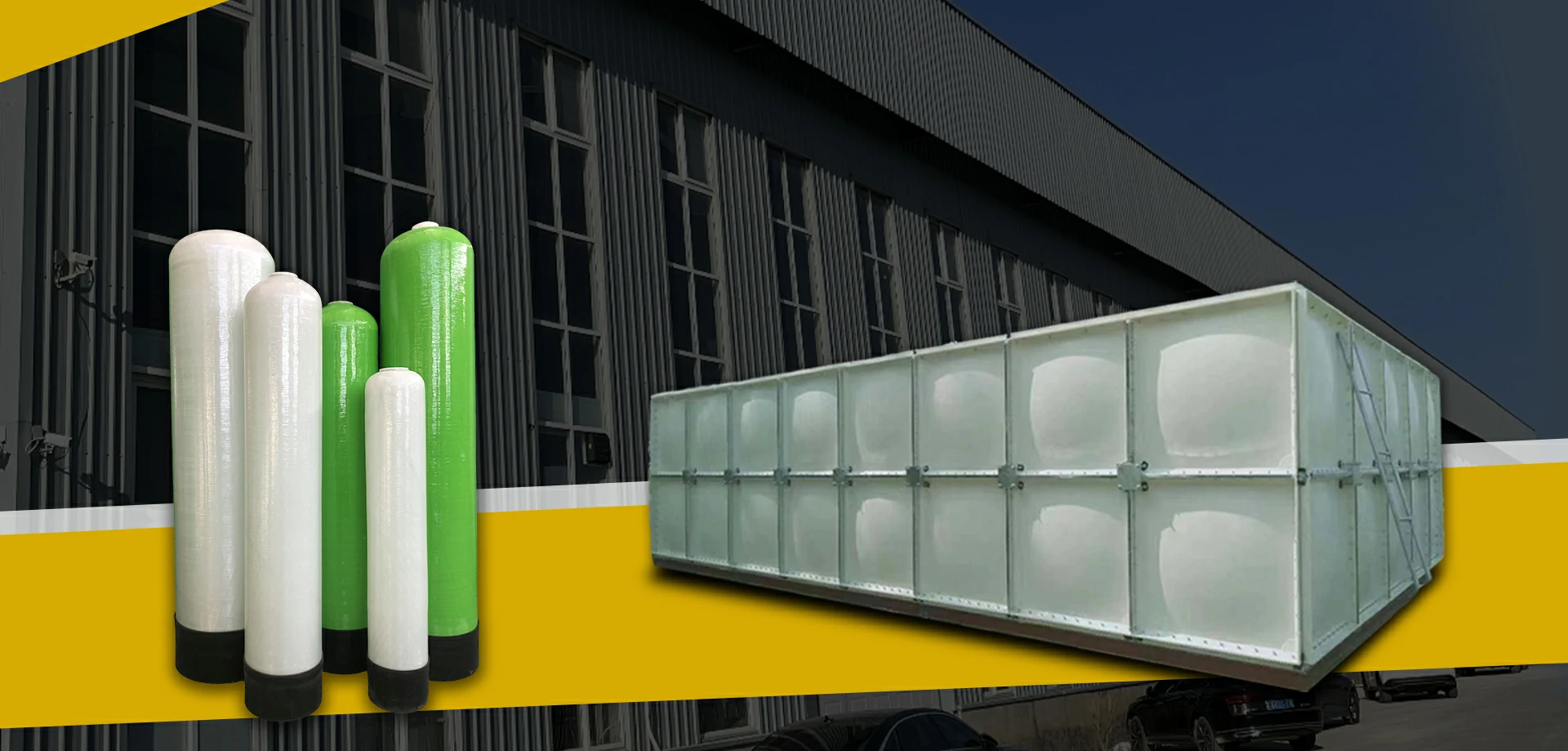

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024