loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Innovative Applications and Benefits of GFRP Grating in Modern Construction Projects

The Evolution and Benefits of GFRP Grating

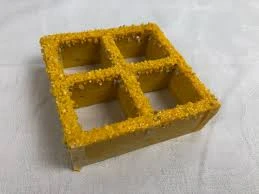

In recent years, the demand for innovative construction materials has escalated significantly, leading to the rise of Glass Fiber Reinforced Polymer (GFRP) grating in various industries. GFRP grating is a composite material made of fiberglass and resin, offering several advantages over traditional materials like steel and wood. This article explores the evolution, benefits, and applications of GFRP grating.

Traditionally, metal and wooden gratings were the go-to choices for applications ranging from industrial flooring to bridge decks. However, these materials often came with substantial drawbacks, including susceptibility to corrosion, rot, and significant weight. The introduction of GFRP grating has revolutionized this landscape. Developed in the late 20th century, GFRP grating quickly gained traction due to its unique properties, such as high strength-to-weight ratio, corrosion resistance, and versatility.

The Evolution and Benefits of GFRP Grating

Corrosion resistance is another standout characteristic of GFRP grating. In industries such as oil and gas, wastewater treatment, and chemical manufacturing, equipment and infrastructure are regularly exposed to harsh environments and corrosive substances. Unlike metal gratings, which can corrode and lead to costly maintenance or replacement, GFRP gratings are inert to many chemicals, ensuring longevity and durability. This property not only extends the lifecycle of the product but also significantly reduces maintenance costs over time.

gfrp grating

GFRP grating also offers enhanced safety features. The surface texture of GFRP can be designed to provide slip-resistance, reducing the risk of accidents in slippery conditions. This aspect is particularly crucial in industrial environments and outdoor applications, where safety is paramount. Additionally, GFRP materials are non-conductive, making them ideal for electrical applications and reducing the risk of accidents related to electrical conductivity.

Furthermore, the versatility of GFRP grating is evident in its wide range of applications. It can be used in various sectors, including marine, architectural, and transportation fields. For example, in the marine industry, GFRP grating is frequently used for docks, walkways, and piers due to its resistance to saltwater corrosion. In architectural applications, GFRP grating can be used as decorative elements, offering an aesthetically pleasing yet functional solution for light gauge structures.

The design flexibility that GFRP offers is another compelling advantage. Available in various colors, sizes, and configurations, GFRP grating allows architects and engineers to customize solutions to fit specific project requirements. This adaptability makes it an attractive choice for projects where both functionality and aesthetics are important.

In conclusion, GFRP grating has emerged as a viable alternative to traditional materials in various industries, thanks to its lightweight nature, corrosion resistance, safety features, and design versatility. As construction and engineering continue to evolve, the demand for materials like GFRP grating will only increase. This innovative product not only meets the modern needs of construction but also contributes to more sustainable practices by reducing maintenance and enhancing durability. In the future, GFRP grating is poised to become a standard component in the development of advanced infrastructures and sustainable construction solutions.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024