loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Innovative Applications of GFRP Gratings in Structural Engineering and Design Solutions

Understanding GFRP Grating A Modern Solution for Industrial Applications

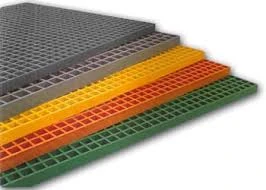

Glass Fiber Reinforced Plastic (GFRP) grating is rapidly gaining recognition in various industries due to its unique properties and advantages over traditional materials. Composed of a polymer resin that is reinforced with glass fibers, GFRP grating is a composite material that offers exceptional strength-to-weight ratio, corrosion resistance, and durability. These features make it an ideal choice for applications where other materials might fail.

Understanding GFRP Grating A Modern Solution for Industrial Applications

Corrosion resistance is another critical benefit of GFRP grating. In environments exposed to moisture, chemicals, or saltwater, traditional metallic grating can corrode over time, leading to structural weaknesses and safety hazards. GFRP grating, on the other hand, is inherently resistant to many aggressive substances, making it an excellent choice for applications in wastewater treatment plants, food processing facilities, and offshore platforms. This characteristic not only extends the lifespan of the grating but also reduces maintenance costs and downtime.

gfrp grating

The versatility of GFRP grating is evidenced by its wide range of applications. It can be found in pedestrian walkways, industrial platforms, and staircases, as well as in various transportation systems. Its non-slip surface provides safety for workers in slippery environments, making it a preferred option in locations where worker safety is a priority. Moreover, GFRP can be manufactured in various colors and configurations, allowing for customization based on specific project requirements.

Environmental sustainability is also a significant consideration in today’s industrial applications, and GFRP grating aligns well with green initiatives. The use of composite materials can lead to lower energy consumption during production compared to metal alternatives. Additionally, the longevity of GFRP reduces the frequency of replacements, further minimizing waste and resource consumption.

Despite its many advantages, it is crucial to consider the application’s specific requirements when choosing GFRP grating. Factors such as load capacity, environmental conditions, and regulatory standards must be thoroughly assessed to ensure optimal performance. Consulting with manufacturers and industry experts can provide valuable insights into the appropriate specifications and installations necessary for success.

In conclusion, GFRP grating stands out as a modern solution for diverse industrial applications due to its lightweight, corrosion-resistant, and durable characteristics. As industries continue to evolve, the demand for sustainable and efficient materials will likely propel the adoption of GFRP solutions, making it a smart choice for businesses looking to enhance safety and reduce costs. Embracing GFRP grating not only leads to operational efficiencies but also contributes to a more sustainable future in industrial practices.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024