loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 19, 2025 02:20

Back to list

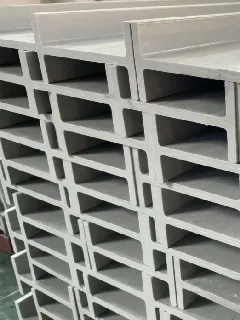

gfrp grating

Fiber reinforced polymers (FRPs) have revolutionized numerous industries with their extraordinary properties, and among them, glass fiber reinforced plastic (GFRP) gratings stand out as a prime example. Users are continually discovering both expected and unexpected advantages that these innovative materials offer. Here, we delve into the unique features, applications, and benefits of GFRP gratings, offering authoritative insights from experienced industry experts.

In environments where electrical conductivity is a concern, GFRP gratings offer a substantial safety benefit. Due to their non-conductive nature, they are preferred in areas where electrical hazards must be minimized. This attribute makes GFRP a safer choice in industrial settings, where the risk of electric shock needs to be mitigated. Furthermore, the customization potential of GFRP gratings adds an additional layer of appeal. Companies can tailor these gratings to suit specific needs, with varying thickness, color, and mesh sizes. This customization not only meets aesthetic and functional requirements but also ensures compliance with standards and specifications in different sectors. As the global emphasis on sustainability grows, GFRP gratings align with environmental goals. Their production involves less energy compared to traditional metals, and their long lifespan reduces waste. Eco-conscious companies view GFRP as a step towards reducing their carbon footprint, making it both an environmentally and economically sound choice. For businesses seeking robust, versatile, and cost-effective solutions for flooring, walkways, and platforms, GFRP gratings emerge as an unparalleled option. Their array of benefits, from superior corrosion resistance to the flexibility of design, make them an essential component in modern construction and infrastructure projects. In conclusion, the adoption of GFRP gratings highlights a significant shift towards innovative material use in manufacturing and construction. Their demonstrated expertise in various challenging environments, backed by trust from professionals across the industry, underscores their status as a material of the future. Through continuous innovation and application, GFRP gratings promise to meet the evolving needs of diverse industries worldwide.

In environments where electrical conductivity is a concern, GFRP gratings offer a substantial safety benefit. Due to their non-conductive nature, they are preferred in areas where electrical hazards must be minimized. This attribute makes GFRP a safer choice in industrial settings, where the risk of electric shock needs to be mitigated. Furthermore, the customization potential of GFRP gratings adds an additional layer of appeal. Companies can tailor these gratings to suit specific needs, with varying thickness, color, and mesh sizes. This customization not only meets aesthetic and functional requirements but also ensures compliance with standards and specifications in different sectors. As the global emphasis on sustainability grows, GFRP gratings align with environmental goals. Their production involves less energy compared to traditional metals, and their long lifespan reduces waste. Eco-conscious companies view GFRP as a step towards reducing their carbon footprint, making it both an environmentally and economically sound choice. For businesses seeking robust, versatile, and cost-effective solutions for flooring, walkways, and platforms, GFRP gratings emerge as an unparalleled option. Their array of benefits, from superior corrosion resistance to the flexibility of design, make them an essential component in modern construction and infrastructure projects. In conclusion, the adoption of GFRP gratings highlights a significant shift towards innovative material use in manufacturing and construction. Their demonstrated expertise in various challenging environments, backed by trust from professionals across the industry, underscores their status as a material of the future. Through continuous innovation and application, GFRP gratings promise to meet the evolving needs of diverse industries worldwide.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024