loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

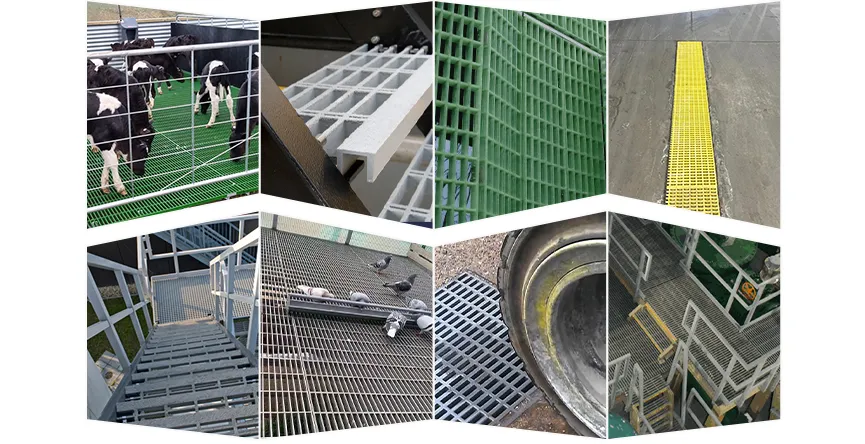

Innovative Applications and Benefits of GFRP Grating in Modern Construction Projects

Understanding GFRP Grating A Comprehensive Overview

Glass Fiber Reinforced Polymer (GFRP) grating has emerged as a highly innovative and efficient solution in various industrial applications. Characterized by its lightweight, strength, and corrosion resistance, GFRP grating has become a preferred choice for environments where traditional materials like steel and aluminum may falter.

GFRP grating is manufactured by combining glass fibers with a polymer matrix, resulting in a composite material that exhibits remarkable mechanical properties. The glass fibers provide tensile strength, while the polymer matrix gives the overall structure its durability and resistance to chemical exposure. This unique combination allows GFRP grating to withstand harsh environmental conditions, making it ideal for industries such as chemical processing, wastewater treatment, and marine applications.

Understanding GFRP Grating A Comprehensive Overview

In addition to its durability, GFRP grating is exceptionally lightweight. This attribute simplifies handling, installation, and transportation, making it an economical choice for many projects. Workers can easily manage GFRP grating panels without the need for heavy machinery, significantly reducing labor costs and installation time.

gfrp grating

Moreover, GFRP grating offers excellent slip resistance, an essential feature for ensuring safety in workplaces that are prone to spills or wet conditions. The surface of GFRP grating can be designed to enhance grip, reducing the likelihood of slips and falls, which is crucial in industrial environments.

Another noteworthy benefit of GFRP grating is its versatility. It can be manufactured in various sizes and shapes, tailored to meet specific project requirements. This adaptability allows for applications ranging from flooring and walkways to platforms and staircases. Furthermore, GFRP grating can be produced in different colors, which can be advantageous for aesthetic purposes or to signal specific hazards.

While the initial cost of GFRP grating may be higher than that of traditional materials, the long-term savings associated with its durability and minimal maintenance requirements often offset these upfront expenditures. Industries increasingly recognize the value of investing in sustainable solutions, and the life cycle cost of GFRP grating positions it as an attractive option.

In conclusion, GFRP grating represents a significant advancement in the field of industrial materials. Its combination of corrosion resistance, lightweight properties, slip resistance, and versatility makes it suitable for a wide range of applications. As industries continue to prioritize safety and durability, GFRP grating stands out as a practical and reliable solution for enhancing operational efficiency and ensuring long-lasting performance.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024