loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Advancements in GFRP Grating Technology for Enhanced Structural Performance and Durability

Understanding GFRP Grating Benefits and Applications

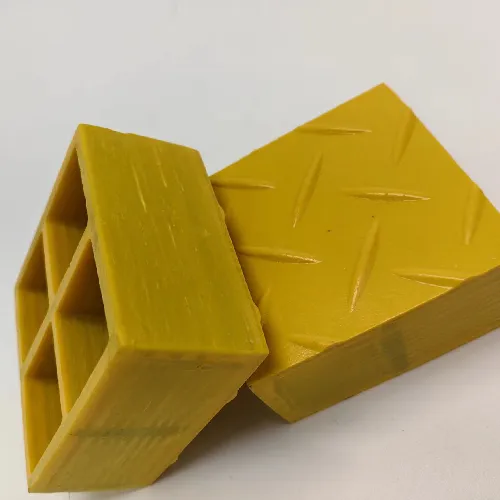

Glass Fiber Reinforced Polymer (GFRP) grating is an innovative material widely used in various industries due to its unique properties and advantages. Comprising a composite of glass fibers and a polymer matrix, GFRP grating offers a lightweight yet robust solution for flooring, walkways, and platforms in both indoor and outdoor environments. This article delves into the benefits and applications of GFRP grating, highlighting why it has become a crucial material in modern construction and industrial design.

Benefits of GFRP Grating

1. Corrosion Resistance One of the standout features of GFRP grating is its exceptional resistance to corrosion. Unlike traditional materials like steel, GFRP does not rust or corrode when exposed to harsh chemicals, saltwater, and other environmental factors. This makes it an ideal choice for applications in chemical processing plants, wastewater treatment facilities, and coastal environments.

2. Lightweight GFRP grating is significantly lighter than metal grating, making it easier to handle and install. This lightweight nature reduces transportation costs and labor requirements, contributing to overall project efficiency. The ease of installation is particularly beneficial for projects with logistical challenges or restricted weight conditions.

3. High Strength-to-Weight Ratio Despite its lightweight characteristics, GFRP grating maintains a high strength-to-weight ratio. It can withstand substantial loads and impacts, making it suitable for heavy-duty applications. The grating is engineered to distribute weight evenly, enhancing its durability and performance under stress.

4. Non-Conductive GFRP is non-conductive, making it a perfect material for electrical applications. It is commonly used in electrical facilities and substations where ibridge gaps are required, reducing the risk of electrical hazards. Additionally, its anti-static properties make it suitable for environments sensitive to static electricity.

5. Customizable and Versatile GFRP grating can be manufactured in various shapes, sizes, and colors. This versatility allows for customization according to specific project needs and aesthetic preferences. Whether for industrial use or architectural design, GFRP grating can blend functionality with visual appeal.

gfrp grating

Applications of GFRP Grating

1. Industrial Flooring GFRP grating is extensively used in industrial settings as flooring in factories, warehouses, and processing plants. Its anti-slip surface ensures worker safety, and its resistance to chemicals makes it ideal for environments exposed to hazardous substances.

2. Walkways and Platforms The lightweight and strong nature of GFRP grating makes it perfect for constructing walkways and platforms. In environments like oil rigs, power plants, and chemical plants, GFRP provides safe and sturdy access routes that can withstand the elements.

3. Marine Applications In marine environments, GFRP grating is used for docks, marinas, and drain covers due to its resistance to seawater and UV radiation. Its ability to endure extreme weather conditions ensures long-lasting performance in coastal areas.

4. Wastewater Treatment The corrosion resistance of GFRP makes it a preferred choice for wastewater treatment facilities. The grating can withstand the aggressive chemicals present in wastewater, providing a reliable and maintenance-free option for these critical infrastructures.

5. Architectural Design Beyond industrial applications, GFRP grating is increasingly being used in contemporary architectural designs. It can be integrated into projects as decorative elements, shading devices, or even as part of the structural framework, offering a modern aesthetic while providing functionality.

Conclusion

In conclusion, GFRP grating represents a technological advancement in material science, offering a range of benefits that cater to the needs of various industries. Its corrosion resistance, lightweight design, high strength-to-weight ratio, and customization options make it an attractive choice for architects and engineers alike. As industries continue to prioritize safety, efficiency, and environmental sustainability, GFRP grating will undoubtedly play a significant role in the future of construction and infrastructure development.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024