loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 16, 2025 15:30

Back to list

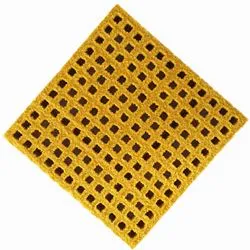

frp platform grating

Glass fiber reinforced polymer (GFRP) bars have revolutionized the construction industry with their unique combination of durability, strength, and lightweight characteristics. Unlike traditional steel reinforcement, GFRP bars offer a corrosion-resistant solution that extends the lifespan of structures exposed to harsh environmental conditions.

However, implementing GFRP bars presents certain challenges which include the initial investment cost that tends to be higher than traditional steel. The returns, however, are seen in the lengthy reduction of maintenance expenses and increased structure longevity, which ultimately contributes to the cost-efficiency of the project. The development of GFRP technology owes much to extensive research and field studies that confirm their effectiveness and durability. Universities and organizations dedicated to materials science have conducted several tests establishing GFRP as a standard for safe and sustainable construction materials. These studies fortify the credibility and trustworthiness associated with using GFRP bars, making them a forward-thinking option for future-proof construction. Product manufacturers are continually innovating within the realm of GFRP technology, striving to enhance its load-bearing capabilities while maintaining lean profiles for aesthetic architectural demands. This innovative spirit is crucial for the ongoing evolution of construction technology, ensuring that GFRP bars remain at the forefront of sustainable building solutions. For decision-makers in the construction field, opting for GFRP bars means investing in a material that promises resilience, economic efficiency, and adaptability. As environmental considerations continue to shape construction practices, incorporating such advanced materials aligns with the global shift towards green building solutions, combining functionality with eco-friendly practices. In summary, glass fiber reinforced polymer bars represent a significant leap forward in reinforcing technology. They balance strength, durability, and environmental resistance, raising the standard for contemporary construction. As these materials continue to evolve, their application will broaden, making them an essential component of modern infrastructure development.

However, implementing GFRP bars presents certain challenges which include the initial investment cost that tends to be higher than traditional steel. The returns, however, are seen in the lengthy reduction of maintenance expenses and increased structure longevity, which ultimately contributes to the cost-efficiency of the project. The development of GFRP technology owes much to extensive research and field studies that confirm their effectiveness and durability. Universities and organizations dedicated to materials science have conducted several tests establishing GFRP as a standard for safe and sustainable construction materials. These studies fortify the credibility and trustworthiness associated with using GFRP bars, making them a forward-thinking option for future-proof construction. Product manufacturers are continually innovating within the realm of GFRP technology, striving to enhance its load-bearing capabilities while maintaining lean profiles for aesthetic architectural demands. This innovative spirit is crucial for the ongoing evolution of construction technology, ensuring that GFRP bars remain at the forefront of sustainable building solutions. For decision-makers in the construction field, opting for GFRP bars means investing in a material that promises resilience, economic efficiency, and adaptability. As environmental considerations continue to shape construction practices, incorporating such advanced materials aligns with the global shift towards green building solutions, combining functionality with eco-friendly practices. In summary, glass fiber reinforced polymer bars represent a significant leap forward in reinforcing technology. They balance strength, durability, and environmental resistance, raising the standard for contemporary construction. As these materials continue to evolve, their application will broaden, making them an essential component of modern infrastructure development.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024