loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

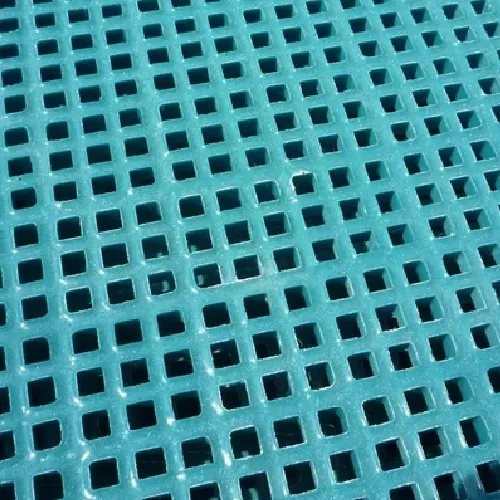

glass reinforced plastic structure

The Role of Glass Reinforced Plastic Structures in Modern Engineering

In recent years, the use of glass reinforced plastic (GRP) structures has gained significant traction across various engineering sectors. With its unique combination of lightweight properties, high strength, and durability, GRP is revolutionizing the way we approach construction, automotive, aerospace, and even marine applications. This article explores the characteristics, benefits, and applications of GRP structures, showcasing why they are becoming an essential component in modern engineering.

Understanding Glass Reinforced Plastic

Glass reinforced plastic is a composite material that consists of a polymer matrix reinforced with glass fibers. The incorporation of glass fibers enhances the overall mechanical properties of plastic, resulting in a material that can withstand considerable stress while maintaining a lower weight compared to traditional materials like steel or aluminum. GRP typically offers excellent resistance to corrosion, making it ideal for environments that may cause other materials to degrade quickly.

The manufacturing process of GRP usually involves techniques such as filament winding, pultrusion, or hand lay-up, which allow for the creation of structures with varying shapes and sizes. These methods enable engineers and designers to tailor the material properties to suit specific applications, optimizing the performance of the finished product.

Benefits of Glass Reinforced Plastic Structures

One of the most noteworthy advantages of GRP is its remarkable strength-to-weight ratio. This characteristic enables engineers to create lighter structures without compromising on strength, which is particularly advantageous in industries where reducing weight can lead to improved efficiency and reduced energy consumption. For example, in aerospace applications, minimizing weight can enhance fuel efficiency and increase payload capacity.

glass reinforced plastic structure

In addition to its lightweight nature, GRP provides excellent resistance to environmental factors such as moisture, UV radiation, and chemical exposure. This durability translates to lower maintenance costs and an extended lifespan for GRP structures. Furthermore, the material can be molded into complex shapes, allowing for innovative designs that would be challenging or impossible to achieve with traditional materials.

Applications of Glass Reinforced Plastic Structures

The versatility of GRP has led to its widespread adoption across various industries. In construction, GRP is used for building facades, roofing materials, and even structural components. Its lightweight nature simplifies transportation and installation, making it a favored choice for construction projects that demand efficiency.

In the automotive sector, GRP is increasingly employed in the manufacture of body panels and structural components. Automakers are leveraging the qualities of GRP to create vehicles that are not only lighter but also more fuel-efficient, aligning with the global push towards sustainability.

The aerospace industry benefits from GRP as well, where it is utilized in components such as fairings and interior structures, contributing to overall aircraft performance and safety. Additionally, the marine industry extensively uses GRP for boat hulls and other components due to its excellent resistance to water abrasion and corrosion.

Conclusion

In conclusion, glass reinforced plastic structures are becoming indispensable in modern engineering. With their unparalleled strength-to-weight ratio, resistance to environmental degradation, and versatility, GRP materials are transforming industries ranging from construction to aerospace. As technology and methods of production continue to evolve, it is likely that we will see even greater innovations and applications of glass reinforced plastic, paving the way for more efficient and durable solutions in our built environment. As engineers and designers increasingly recognize the potential of GRP, we can anticipate a future where this composite material plays a central role in shaping sustainable and robust structures across the globe.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024