loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 13, 2025 03:12

Back to list

Holiday Special Offers GRP FRP Gratings Fiberglass Grates

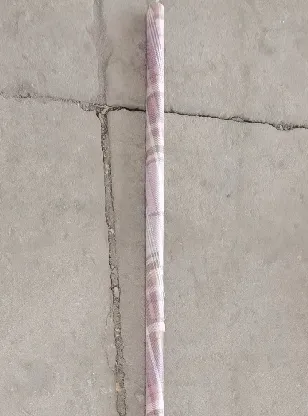

Grating anti-slip solutions have become indispensable in diverse industries where safety and efficiency are paramount. As our world steadily transitions towards enhanced safety standards, businesses in manufacturing, oil and gas, transportation, and public infrastructure are increasingly adopting these solutions. With firsthand experience in both recommending and implementing grating anti-slip products, I offer an exhaustive look at why these silvers of safety are considered revolutionary.

Trustworthiness can be gleaned from the testimonials and case studies that feature these products' usage across various real-world scenarios. For instance, steel grating with an anti-slip coating has revolutionized safety on marine vessels by providing traction without the heavy maintenance that wood or pure aluminum might require. In manufacturing plants, fiberglass gratings offer a non-magnetic and non-conductive alternative, making them essential in electrical utility and telecommunications facilities. The practical applications of these grating systems are vast; they are employed on platforms, walkways, stair treads, and ladders—each playing an indispensable role in maintaining operational safety across industries. Furthermore, the installation of grating anti-slip solutions is also economically beneficial. While initial costs might be higher compared to regular flooring solutions, the return on investment is significant. Companies report dwindling accidents and down-time costs, which far outweigh the upfront expenses. These savings, coupled with an increase in worker safety and morale, make a compelling business case. Environmentally conscious manufacturers are also delving into producing recyclable and sustainable products without sacrificing quality and reliability. Being able to deter natural challenges while maintaining environmental integrity highlights these products’ holistic approach to industrial challenges. In conclusion, grating anti-slip solutions are not merely a product but a cornerstone of modern safety engineering. The seamless integration of advanced materials and design innovation epitomizes the pinnacle of safety solutions in industries fraught with potential hazards. As businesses continue to prioritize safety, the evolution and application of grating anti-slip technologies will only gain prominence. In an era where employee safety directly correlates with business efficacy, these technologies assure that companies maintain their competitive edge while staunchly adhering to the highest standards of safety and reliability. Through continuous research and development, grating anti-slip solutions will undoubtedly lead the way in fostering safer industrial practices globally.

Trustworthiness can be gleaned from the testimonials and case studies that feature these products' usage across various real-world scenarios. For instance, steel grating with an anti-slip coating has revolutionized safety on marine vessels by providing traction without the heavy maintenance that wood or pure aluminum might require. In manufacturing plants, fiberglass gratings offer a non-magnetic and non-conductive alternative, making them essential in electrical utility and telecommunications facilities. The practical applications of these grating systems are vast; they are employed on platforms, walkways, stair treads, and ladders—each playing an indispensable role in maintaining operational safety across industries. Furthermore, the installation of grating anti-slip solutions is also economically beneficial. While initial costs might be higher compared to regular flooring solutions, the return on investment is significant. Companies report dwindling accidents and down-time costs, which far outweigh the upfront expenses. These savings, coupled with an increase in worker safety and morale, make a compelling business case. Environmentally conscious manufacturers are also delving into producing recyclable and sustainable products without sacrificing quality and reliability. Being able to deter natural challenges while maintaining environmental integrity highlights these products’ holistic approach to industrial challenges. In conclusion, grating anti-slip solutions are not merely a product but a cornerstone of modern safety engineering. The seamless integration of advanced materials and design innovation epitomizes the pinnacle of safety solutions in industries fraught with potential hazards. As businesses continue to prioritize safety, the evolution and application of grating anti-slip technologies will only gain prominence. In an era where employee safety directly correlates with business efficacy, these technologies assure that companies maintain their competitive edge while staunchly adhering to the highest standards of safety and reliability. Through continuous research and development, grating anti-slip solutions will undoubtedly lead the way in fostering safer industrial practices globally.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024