loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 10, 2025 10:24

Back to list

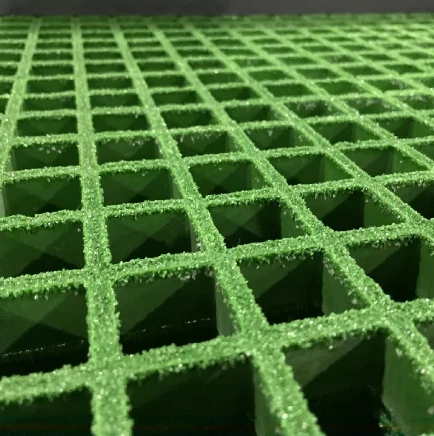

Holiday Special Offers GRP FRP Gratings Fiberglass Grates

The integration of FRP grating in various industries has sparked a transformative change, providing an innovative alternative that promotes safety and efficiency in structural applications. FRP, or Fiber Reinforced Polymer, grating is renowned for its lightweight, high-strength properties, making it an exceptional choice for projects demanding durability and resistance against harsh environmental conditions.

Safety is another critical aspect that elevates FRP grating's stature in the industry. Its non-conductive properties eliminate electrical hazards, a significant advantage in plants and facilities where electricity is prevalent. Additionally, the grating is designed to be slip-resistant, a feature essential for employee safety in workplaces where wet and oily conditions are common. The authoritative stance of FRP is validated by supportive data and studies demonstrating its performance. Research conducted in industrial settings reveals that facilities utilizing FRP grating report fewer safety incidents, lower maintenance costs, and improved employee satisfaction due to safer working conditions. Industry standards and tests further certify FRP's capabilities, proving its reliability as a structural component. Trust in FRP grating is bolstered by its track record in high-stakes environments. Companies adopting FRP solutions invariably witness not just the practical benefits but also an alignment with modern sustainability goals. FRP is recyclable and less resource-intensive to produce compared to traditional metal gratings, supporting environmental objectives and corporate social responsibility standards. In conclusion, FRP grating stands as a testament to advanced engineering that meets the complex demands of today's industrial landscapes. Its resilience, backed by scientific validation and real-world application, positions it as a preferred choice for forward-thinking companies. As the industry increasingly embraces innovation, FRP grating is set to become synonymous with durability, safety, and efficiency, leading the charge toward more sustainable and cost-effective future infrastructures.

Safety is another critical aspect that elevates FRP grating's stature in the industry. Its non-conductive properties eliminate electrical hazards, a significant advantage in plants and facilities where electricity is prevalent. Additionally, the grating is designed to be slip-resistant, a feature essential for employee safety in workplaces where wet and oily conditions are common. The authoritative stance of FRP is validated by supportive data and studies demonstrating its performance. Research conducted in industrial settings reveals that facilities utilizing FRP grating report fewer safety incidents, lower maintenance costs, and improved employee satisfaction due to safer working conditions. Industry standards and tests further certify FRP's capabilities, proving its reliability as a structural component. Trust in FRP grating is bolstered by its track record in high-stakes environments. Companies adopting FRP solutions invariably witness not just the practical benefits but also an alignment with modern sustainability goals. FRP is recyclable and less resource-intensive to produce compared to traditional metal gratings, supporting environmental objectives and corporate social responsibility standards. In conclusion, FRP grating stands as a testament to advanced engineering that meets the complex demands of today's industrial landscapes. Its resilience, backed by scientific validation and real-world application, positions it as a preferred choice for forward-thinking companies. As the industry increasingly embraces innovation, FRP grating is set to become synonymous with durability, safety, and efficiency, leading the charge toward more sustainable and cost-effective future infrastructures.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024