loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

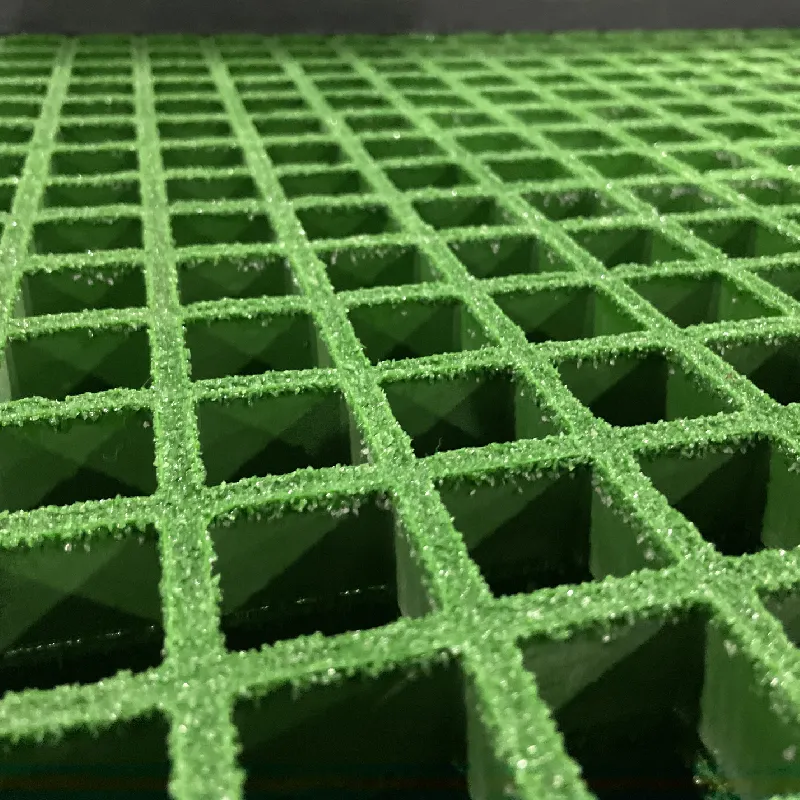

grating frp

Grating FRP, also known as Fiber Reinforced Plastic Grating, has emerged as a revolutionary material in industrial flooring and infrastructure applications. Combining lightweight properties with formidable strength, FRP grating is engineered to meet the rigorous demands of heavy-duty environments. A broad spectrum of industries has shifted towards using FRP grating due to its unique characteristics that provide superior performance and long-term benefits.

Experience of Industry Users with Grating FRP

Over the years, industries ranging from chemical processing plants to offshore oil rigs have adopted FRP grating due to its exceptional corrosion resistance. Professionals with firsthand experience in using grating FRP often highlight how this material dramatically reduces maintenance costs and enhances operational efficiency. Unlike traditional materials such as steel or wood, FRP grating withstands harsh chemical exposures and extreme environmental conditions, thus proving a cost-effective solution in the long run.

In wastewater treatment facilities, for instance, operators have found that FRP grating remains unaffected by constant moisture and aggressive substances, resulting in fewer replacements and repairs. This durability has turned skeptics into advocates, as they observe the ongoing performance advantages and return on investment.

Expertise in Fiber Reinforced Plastic Technology

FRP combines advanced polymer technology with engineering expertise to manufacture robust grating solutions. By weaving glass fibers with resin, engineers create a composite matrix that delivers unrivaled strength-to-weight ratio. This strategic combination not only ensures structural integrity but also offers significant weight savings compared to metal alternatives.

In domains requiring electrical insulation, such as power plants, FRP grating is a preferred choice due to its non-conductive nature. Industry experts advise specifying grating FRP in environments where electrostatic discharge could pose a risk to operations or safety. Furthermore, FRP’s inherent fire retardancy keeps facilities safer, aligning with stringent industry safety standards.

Authoritativeness in the Marketplace

grating frp

Global industrial leaders continuously validate the authority of grating FRP in critical applications. Associations and certification bodies recognize and certify FRP grating for its robust performance characteristics. Suppliers and manufacturers invest heavily in research and development to refine and innovate FRP technology, emphasizing its role as an authoritative material in modern construction and industrial planning.

Companies like Fibergrate and Strongwell, renowned for their production quality, set benchmarks in the FRP grating industry, thereby influencing global standards. Their certifications and adherence to international norms drive confidence and capability among end-users in selecting FRP grating for demanding projects.

Trustworthiness in Deployment

When assessing materials for infrastructure projects, trustworthiness remains paramount. Grating FRP is valued for its predictable and consistent performance. Years of documented case studies and third-party evaluations contribute to a track record that underscores its reliability. Facility managers trust FRP grating not only for its immediate benefits but also for the longevity and sustainability it promises over decades of service.

From a safety perspective, FRP grating's slip-resistant surface reduces workplace accidents, fostering a safer environment for employees and visitors. This trust is further bolstered by customizable options that cater to specific project needs, ensuring that organizations can rely on tailored solutions without compromising quality.

Conclusion

Grating FRP offers a compelling narrative for industries that demand performance, resilience, and innovation. It stands as a testament to modern material science, balancing practical benefits with long-term market value. Whether you’re looking to enhance efficiency, maintain safety, or achieve cost savings, FRP grating embodies a trusted investment for enduring success in industrial applications. With its growing reputation and widespread adoption, FRP grating truly commands a distinct and essential place in the competitive landscape of industrial materials.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024