loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1 月 . 15, 2025 09:09

Back to list

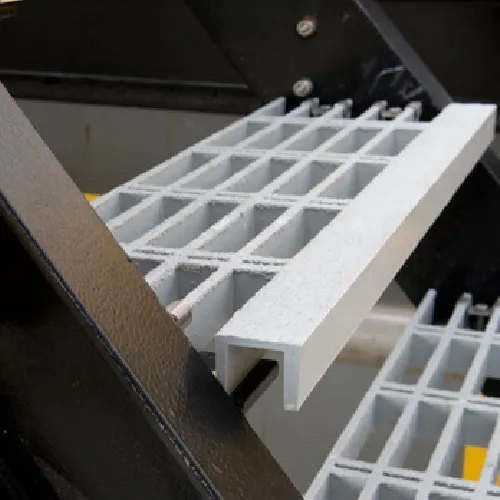

frp micro mesh grating

Fiberglass Reinforced Plastic (FRP) grating is revolutionizing how industries approach infrastructure projects, promising a future where reliability, longevity, and efficiency are no longer mutually exclusive. In an era where industrial performance must align with environmental sustainability, FRP grating stands out as an eco-friendly alternative that meets stringent demands across diverse sectors.

A deeper dive into the expertise and authority of FRP grating reveals its impressive adaptability. Industries are continuously exploring innovative ways to incorporate FRP into their operations, guided by evidence-based research that underpins the material's efficacy. Structural testing has validated the load-bearing capacity of various FRP grating configurations, ensuring compliance with international standards. When discussing trustworthiness, the reputation of manufacturers in this niche cannot be overstated. Leading companies are often ISO-certified, their products meeting rigorous international benchmarks, which instills confidence among engineers, contractors, and investors alike. Transparent customer service and a commitment to quality further enhance the trust associated with FRP grating products. In conclusion, FRP grating represents a leap forward in product innovation within industrial applications, combining practical benefits with long-term cost-effectiveness. Its unmatched performance in challenging settings makes it an indispensable choice for businesses aiming to optimize infrastructure while adhering to environmental and safety standards. As industries continue to prioritize sustainability and efficiency, the adoption of FRP grating is not only a prudent investment but an essential step toward a more resilient infrastructure landscape.

A deeper dive into the expertise and authority of FRP grating reveals its impressive adaptability. Industries are continuously exploring innovative ways to incorporate FRP into their operations, guided by evidence-based research that underpins the material's efficacy. Structural testing has validated the load-bearing capacity of various FRP grating configurations, ensuring compliance with international standards. When discussing trustworthiness, the reputation of manufacturers in this niche cannot be overstated. Leading companies are often ISO-certified, their products meeting rigorous international benchmarks, which instills confidence among engineers, contractors, and investors alike. Transparent customer service and a commitment to quality further enhance the trust associated with FRP grating products. In conclusion, FRP grating represents a leap forward in product innovation within industrial applications, combining practical benefits with long-term cost-effectiveness. Its unmatched performance in challenging settings makes it an indispensable choice for businesses aiming to optimize infrastructure while adhering to environmental and safety standards. As industries continue to prioritize sustainability and efficiency, the adoption of FRP grating is not only a prudent investment but an essential step toward a more resilient infrastructure landscape.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024