loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 20, 2025 08:48

Back to list

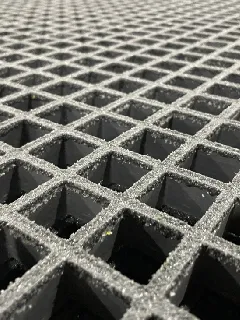

frp micro mesh grating

In the industrial and architectural realms, the demand for durable and versatile materials is paramount. Among the unsung heroes of modern construction and manufacturing is the grating wire mesh. This robust material, characterized by intersecting series of parallel wires, is not only essential for various sectors but also provides a plethora of benefits. Drawing from extensive industry experience, let’s dive into the multifaceted world of grating wire mesh.

The authoritativeness of grating wire mesh within industrial settings cannot be overstated. It has been rigorously tested to meet international safety and performance standards. Organizations often opt for mesh that aligns with their operational requirements, ensuring it conforms to stringent codes and regulations. This compliance not only guarantees performance but also enhances a company's reputation for safety and quality. Trustworthiness in grating wire mesh products is predicated on choosing reputable manufacturers who adhere to high standards of production and quality assurance. It's essential, therefore, to partner with suppliers who have an established track record and are recognized for their commitment to excellence. Reliable suppliers routinely offer documentation and certifications that affirm the mesh’s quality, providing peace of mind for engineers and purchasers. In conclusion, grating wire mesh stands as a cornerstone of industrial and architectural applications alike. Its unique combination of strength, adaptability, and aesthetic potential ensures that it continues to be an indispensable material across multiple domains. By prioritizing material quality and compliance, stakeholders can leverage this versatile solution to its fullest extent, ensuring safety, efficiency, and design integrity in their projects.

The authoritativeness of grating wire mesh within industrial settings cannot be overstated. It has been rigorously tested to meet international safety and performance standards. Organizations often opt for mesh that aligns with their operational requirements, ensuring it conforms to stringent codes and regulations. This compliance not only guarantees performance but also enhances a company's reputation for safety and quality. Trustworthiness in grating wire mesh products is predicated on choosing reputable manufacturers who adhere to high standards of production and quality assurance. It's essential, therefore, to partner with suppliers who have an established track record and are recognized for their commitment to excellence. Reliable suppliers routinely offer documentation and certifications that affirm the mesh’s quality, providing peace of mind for engineers and purchasers. In conclusion, grating wire mesh stands as a cornerstone of industrial and architectural applications alike. Its unique combination of strength, adaptability, and aesthetic potential ensures that it continues to be an indispensable material across multiple domains. By prioritizing material quality and compliance, stakeholders can leverage this versatile solution to its fullest extent, ensuring safety, efficiency, and design integrity in their projects.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024