loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

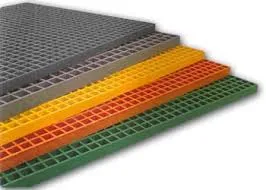

GRP Grating Covers for Enhanced Safety and Durability in Industrial Applications

The Importance of GRP Grating Covers in Modern Infrastructure

In today's world, where infrastructure plays a pivotal role in our daily lives, the materials we use are incredibly important. Among the various types of materials available, Glass Reinforced Plastic (GRP) has emerged as a preferred choice for many applications, especially in the context of grating covers. This article explores the significance of GRP grating covers, their advantages, and their applications across different industries.

What is GRP?

Glass Reinforced Plastic, or GRP, is a composite material made from a polymer matrix reinforced with glass fibers. This combination gives GRP unique properties, making it an excellent choice for various applications. The high strength-to-weight ratio, corrosion resistance, and durability of GRP make it particularly attractive for use in environments that require robust solutions.

Benefits of GRP Grating Covers

1. Corrosion Resistance One of the standout features of GRP is its resistance to corrosion. This property makes GRP grating covers highly suitable for environments that are exposed to harsh chemicals, such as wastewater treatment facilities, chemical processing plants, and marine applications. Unlike traditional materials like steel or aluminum, GRP grating does not rust or degrade when exposed to corrosive substances, resulting in lower maintenance costs and longer service life.

2. Lightweight GRP grating covers are significantly lighter than their metal counterparts. This lightweight nature not only facilitates easier installation but also reduces the overall load on supporting structures. In settings where large areas need to be covered, the reduced weight of GRP can lead to considerable savings in transportation and labor costs.

3. Safety Safety is a paramount concern in industrial settings, and GRP grating covers enhance safety in several ways. They typically feature a slip-resistant surface, which minimizes the risk of accidents due to slips and falls. Additionally, GRP does not conduct electricity, making it a safer choice for applications near electrical components or in environments prone to electrical hazards.

grp grating cover

4. Versatility GRP grating covers are versatile and can be customized to meet specific requirements. They are available in various designs, sizes, and colors, allowing them to fit seamlessly into different architectural styles and functional needs. Whether employed in pedestrian walkways, vehicular access areas, or industrial platforms, GRP grating can be tailored to suit the application.

5. Environmental Impact As the world increasingly moves towards sustainability, GRP materials are becoming more appealing due to their environmentally friendly properties. Many GRP products are manufactured using recycled materials, and the production process generally results in lower emissions compared to traditional materials. Additionally, the longevity of GRP products contributes to reduced waste over time.

Applications of GRP Grating Covers

The applications of GRP grating covers are extensive. They are widely used in sectors such as

- Water Treatment In water and wastewater treatment facilities, GRP grating covers provide safe access to critical areas while resisting corrosive environments. - Industrial Manufacturing Factories benefit from GRP grating in various applications, from flooring to access platforms, where strength and durability are paramount. - Marine Environments Ports and docks often utilize GRP grating covers due to their resistance to saltwater corrosion, ensuring safety and longevity in challenging conditions. - Infrastructure In pedestrian and vehicular walkways, GRP grating offers a lightweight, durable, and visually appealing solution that conforms to safety standards.

Conclusion

In an era where the integrity and efficiency of infrastructure are under constant scrutiny, GRP grating covers stand out as a solution that combines strength, safety, and sustainability. Their versatile applications across various industries highlight their importance in modern infrastructure. As we progress further into the future, the role of innovative materials like GRP will undoubtedly continue to grow, offering reliable solutions to the challenges we face today. Embracing GRP grating covers is not only an investment in material performance but also a commitment to a safer and more sustainable future.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024