loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 19, 2025 08:09

Back to list

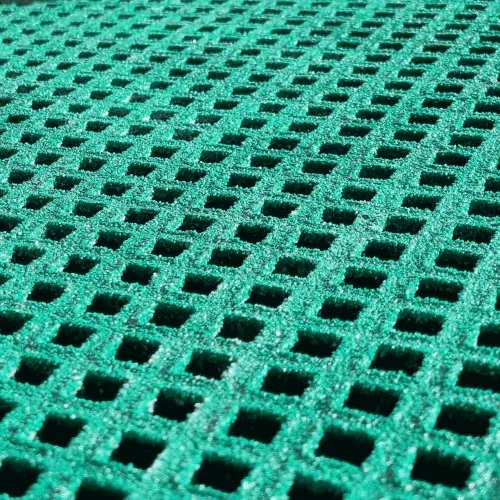

grp mini mesh grating

Fiber-reinforced polymer (FRP) technologies have revolutionized modern construction materials, and among the standout products are GRP (Glass Reinforced Polymer) gratings. Celebrated for their incredible durability, versatility, and resilience, GRP gratings are becoming a preferred choice for a wide range of industries. This innovative material perfectly balances strength and lightness, making it a sought-after solution for architects and engineers alike. Here's why GRP gratings should be on your radar if you're considering material upgrades.

Installation of GRP gratings is both time-efficient and straightforward compared to heavier materials like steel. Their lightweight nature means that special lifting equipment is generally unnecessary, reducing labor costs and minimizing installation time. For project managers and contractors, this translates to a more efficient use of resources and faster project completion times, offering an edge in competitive project environments where time and cost efficiency are critical metrics of success. Environmental considerations are more important than ever, and GRP gratings hit the mark in this area as well. The production process of GRP generates less waste compared to traditional materials, and the end products are often longer lasting, reducing the frequency of replacements. This longevity contributes to sustainability efforts by lessening the need for resource-intensive manufacturing cycles, aligning with eco-friendly construction practices. Moreover, from an aesthetic perspective, GRP gratings offer a modern, clean look that can enhance the visual appeal of both industrial and commercial spaces. Its availability in multiple colors and finishes means it can seamlessly blend into an existing environment or serve as a standout design feature. This ability to provide both functional and aesthetic benefits makes GRP gratings a multifaceted solution suitable for contemporary applications. To conclude, GRP gratings represent a shift towards smarter, more sustainable construction materials that do not compromise on safety, functionality, or design. As industries continue to demand materials that offer long-term performance and cost efficiencies, GRP gratings present an unparalleled option. By choosing GRP, industries not only invest in a reliable material but also in a solution that supports future-forward, sustainable development goals. It’s a clear choice for industry pioneers focused on durability, safety, and environmental responsibility.

Installation of GRP gratings is both time-efficient and straightforward compared to heavier materials like steel. Their lightweight nature means that special lifting equipment is generally unnecessary, reducing labor costs and minimizing installation time. For project managers and contractors, this translates to a more efficient use of resources and faster project completion times, offering an edge in competitive project environments where time and cost efficiency are critical metrics of success. Environmental considerations are more important than ever, and GRP gratings hit the mark in this area as well. The production process of GRP generates less waste compared to traditional materials, and the end products are often longer lasting, reducing the frequency of replacements. This longevity contributes to sustainability efforts by lessening the need for resource-intensive manufacturing cycles, aligning with eco-friendly construction practices. Moreover, from an aesthetic perspective, GRP gratings offer a modern, clean look that can enhance the visual appeal of both industrial and commercial spaces. Its availability in multiple colors and finishes means it can seamlessly blend into an existing environment or serve as a standout design feature. This ability to provide both functional and aesthetic benefits makes GRP gratings a multifaceted solution suitable for contemporary applications. To conclude, GRP gratings represent a shift towards smarter, more sustainable construction materials that do not compromise on safety, functionality, or design. As industries continue to demand materials that offer long-term performance and cost efficiencies, GRP gratings present an unparalleled option. By choosing GRP, industries not only invest in a reliable material but also in a solution that supports future-forward, sustainable development goals. It’s a clear choice for industry pioneers focused on durability, safety, and environmental responsibility.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024