loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

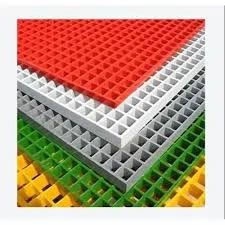

grp grating systems

Grating Systems An Overview of GRP Grating Technology

GRP (Glass Reinforced Plastic) grating systems have emerged as a pivotal technological advancement in various industrial applications, combining strength, durability, and lightweight properties. These systems are increasingly favored in marine, chemical, and infrastructure sectors due to their exceptional resistance to corrosion, ease of installation, and low maintenance requirements.

One of the most significant advantages of GRP grating is its superior resistance to corrosive environments. Traditional materials like steel or aluminum often succumb to rust and degradation when exposed to harsh chemicals or moisture. In contrast, GRP is manufactured through a process that embeds glass fibers into a resin matrix, creating a product that can withstand aggressive environments without compromising structural integrity. This feature not only extends the lifespan of the grating but also reduces replacement costs significantly over time.

Grating Systems An Overview of GRP Grating Technology

Safety is paramount in industrial environments, and GRP grating systems contribute to enhanced workplace safety. Many GRP gratings come with anti-slip surfaces, providing better traction and minimizing the risk of accidents in wet or hazardous conditions. This feature is crucial in areas such as factories, ports, and oil rigs, where safety protocols must be strictly adhered to.

grp grating systems

The versatility of GRP grating systems is another noteworthy benefit. They can be tailored to meet specific design and load requirements, available in various styles, colors, and sizes. This flexibility allows for seamless integration into existing infrastructure while ensuring compliance with regulatory standards. Furthermore, manufacturers offer custom solutions for specialized applications, further expanding the utility of GRP grating systems across multiple industries.

Sustainability is increasingly becoming a factor in material selection, and GRP grating systems hold an edge in this regard. As a non-corrosive material, GRP does not leach harmful substances into the environment, making it a more eco-friendly choice. Moreover, advancements in recycling technologies have made it possible to recover GRP materials at the end of their life cycle, contributing to a circular economy.

When it comes to cost-effectiveness, GRP grating systems provide excellent value. The initial investment may be higher than traditional materials; however, their long lifespan, reduced maintenance costs, and energy-efficient properties often offset the upfront spending. In many cases, organizations find that switching to GRP gratings leads to lower total cost of ownership.

In conclusion, GRP grating systems stand out for their combination of durability, safety, lightweight nature, and economic advantages. As industries continue to evolve, the demand for innovative materials that can meet stringent demands in terms of performance and sustainability will only grow. GRP grating technology is well-positioned to meet these challenges, reinforcing its importance in modern industrial applications. As we advance into a future that prioritizes efficiency and safety, GRP grating systems will undoubtedly play a crucial role in reshaping industrial practices.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024