loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 11, 2025 03:11

Back to list

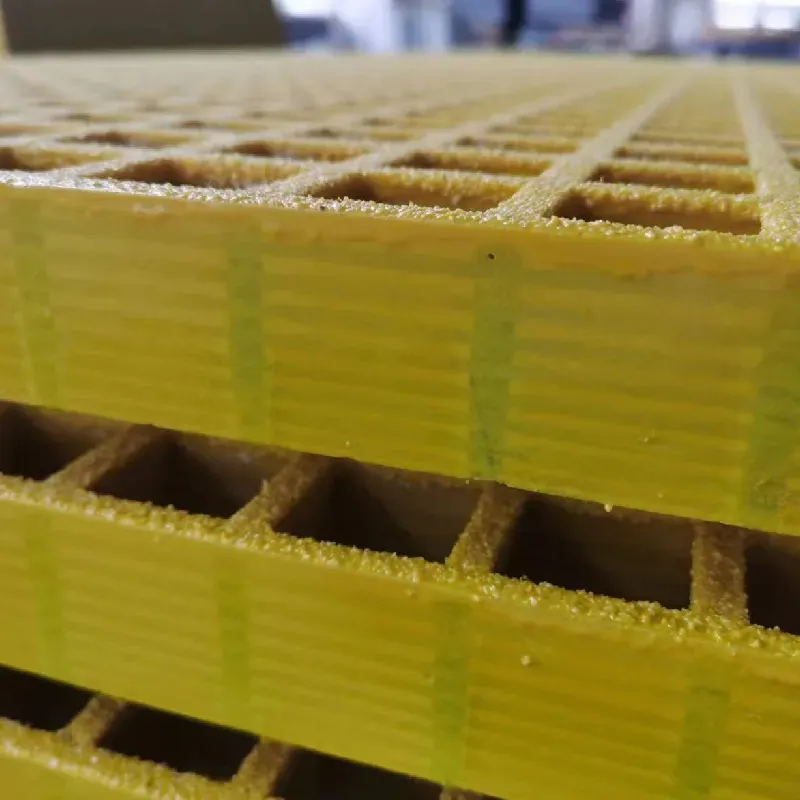

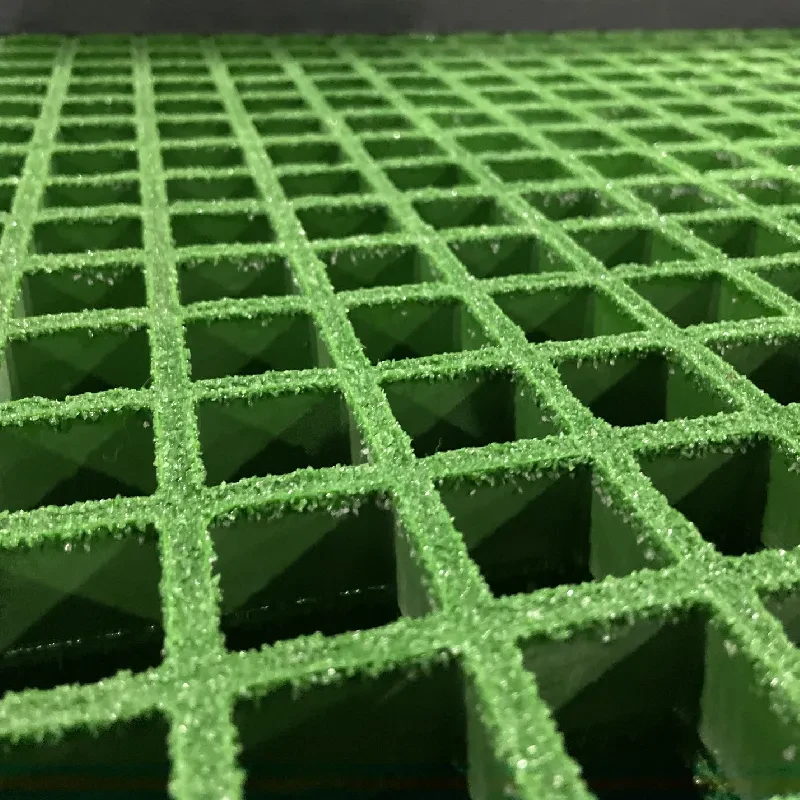

grp mini mesh grating

In the world of industrial flooring solutions, GRP mesh flooring is increasingly gaining prominence due to its unparalleled durability and safety features. As industries evolve and safety standards become more stringent, the selection of the right flooring material can have significant implications for both operational efficiency and worker safety. For industries requiring robust, non-slip, and corrosion-resistant flooring, GRP (Glass Reinforced Plastic) mesh flooring emerges as an indisputable choice.

Moreover, the flexibility in design and installation makes GRP mesh flooring a preferred choice for various industrial applications. It can be easily tailored to specific project requirements, offering customizable size, thickness, and color options to suit different environments and aesthetic needs. The ease of installation is another noteworthy advantage, as the lightweight nature of GRP panels simplifies handling and placement, allowing for quicker and more efficient installation processes that minimize disruption to industrial operations. Environmental consciousness is rising across all sectors, and businesses are increasingly seeking sustainable solutions. GRP mesh flooring stands out in this regard, being an environmentally friendly option. It is fully recyclable at the end of its life span, reducing the environmental impact and aligning with the sustainable goals of forward-thinking companies. For industry leaders and decision-makers, investing in GRP mesh flooring signifies a commitment to safety, efficiency, and sustainability. When evaluating flooring options, companies should consider not only the initial installation costs but the long-term benefits of durability, reduced maintenance, and enhanced safety that GRP flooring solutions provide. By choosing GRP mesh flooring, businesses are well-equipped to meet both current and future demands of industrial operations. In conclusion, GRP mesh flooring excels in offering a modern, effective, and versatile solution for demanding industrial environments. Its combination of strength, safety, and sustainability positions it as an industry leader in flooring materials. As markets continue to evolve, the adoption of GRP mesh floors can provide industries with the competitive edge needed to thrive in a challenging landscape.

Moreover, the flexibility in design and installation makes GRP mesh flooring a preferred choice for various industrial applications. It can be easily tailored to specific project requirements, offering customizable size, thickness, and color options to suit different environments and aesthetic needs. The ease of installation is another noteworthy advantage, as the lightweight nature of GRP panels simplifies handling and placement, allowing for quicker and more efficient installation processes that minimize disruption to industrial operations. Environmental consciousness is rising across all sectors, and businesses are increasingly seeking sustainable solutions. GRP mesh flooring stands out in this regard, being an environmentally friendly option. It is fully recyclable at the end of its life span, reducing the environmental impact and aligning with the sustainable goals of forward-thinking companies. For industry leaders and decision-makers, investing in GRP mesh flooring signifies a commitment to safety, efficiency, and sustainability. When evaluating flooring options, companies should consider not only the initial installation costs but the long-term benefits of durability, reduced maintenance, and enhanced safety that GRP flooring solutions provide. By choosing GRP mesh flooring, businesses are well-equipped to meet both current and future demands of industrial operations. In conclusion, GRP mesh flooring excels in offering a modern, effective, and versatile solution for demanding industrial environments. Its combination of strength, safety, and sustainability positions it as an industry leader in flooring materials. As markets continue to evolve, the adoption of GRP mesh floors can provide industries with the competitive edge needed to thrive in a challenging landscape.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024