loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

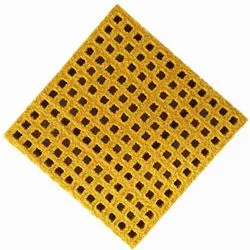

Mini Mesh Grating for Efficient Light Management and Enhanced Performance

Understanding GRP Mini Mesh Grating Benefits and Applications

GRP (Glass Reinforced Plastic) mini mesh grating has become an increasingly popular choice in various industries due to its unique properties and benefits. This type of grating is engineered from a combination of glass fibers and resin, which results in a lightweight yet incredibly strong material. In this article, we will explore the characteristics, advantages, and applications of GRP mini mesh grating.

One of the primary features of GRP mini mesh grating is its lightweight nature. Compared to traditional steel grating, GRP offers a significant reduction in weight without compromising structural integrity. This makes it easier to handle, install, and transport, reducing labor costs and improving efficiency on the job site. The reduced weight also means that it can be used in places where traditional materials would be too heavy or impractical.

Understanding GRP Mini Mesh Grating Benefits and Applications

In addition to its physical properties, GRP mini mesh grating is also highly versatile in terms of design. It can be manufactured in various sizes and configurations to meet the specific requirements of a project. Whether you need a custom size for a unique application or a standard solution, GRP grating can be tailored to fit. This flexibility allows for seamless integration into existing structures and systems.

grp mini mesh grating

Another important aspect of GRP mini mesh grating is its slip resistance. The surface can be designed with textured profiles, significantly enhancing grip and safety, especially in wet or slippery conditions. This feature is particularly advantageous in industrial settings, where worker safety is paramount. Whether used on walkways, stairs, or platforms, GRP grating helps prevent slips and falls, contributing to a safer workplace.

The environmental impact of GRP mini mesh grating is also a consideration worth noting. As industries move towards sustainability, GRP materials can offer a more eco-friendly solution. They are not only durable and long-lasting, reducing the need for frequent replacements, but they can also be recycled at the end of their life cycle, aligning with sustainable practices.

Applications of GRP mini mesh grating are vast and varied. In the construction industry, it is commonly used for walkways, platforms, and vehicle access areas. In the manufacturing sector, it is utilized for machine guards and flooring, particularly in settings where chemicals are present. The mining and oil industries have also recognized the advantages of using GRP grating for elevated walkways and platforms due to its non-conductive properties.

In conclusion, GRP mini mesh grating stands out as a superior alternative to traditional grating materials due to its lightweight strength, corrosion resistance, slip safety, and environmental benefits. Its ability to be customized for specific applications enhances its desirability across numerous industries. As more businesses recognize the advantages of GRP materials, we can expect to see an increase in their adoption, making GRP mini mesh grating a crucial component in creating safe, reliable, and sustainable working environments.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024