loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1 月 . 15, 2025 09:23

Back to list

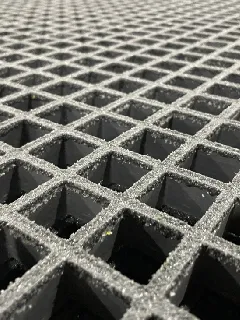

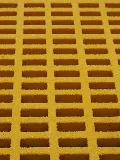

grp mini mesh grating

GRP open mesh grating has emerged as a revolutionary solution for industrial flooring and walkway systems, recognized for its durability, versatility, and safety features. This product stands out in the market primarily due to its corrosion resistance, lightweight structure, and high strength-to-weight ratio, offering compelling reasons for its selection across various industries.

Authoritative sources, including engineering reports and safety audits, highlight GRP grating's superior performance over traditional materials. Studies have demonstrated its resistance to fire, chemicals, and UV radiation, underscoring its applicability in stringent environments. Furthermore, global standards such as those from ASTM and ISO provide guidelines that GRP grating products adhere to, ensuring compliance and quality assurance. In terms of experience, users of GRP open mesh grating report significant benefits including long-term cost savings due to reduced maintenance requirements. The lightweight nature of GRP grating simplifies installation procedures, allowing for quicker project completion and less labor-intensive processes. This efficiency translates to reduced operational downtime, enhancing productivity. Trustworthiness is further amplified through the product's traceable supply chain and rigorous quality control measures. Leading manufacturers offer extensive warranties and certification, ensuring that end-users receive a product that upholds both performance promises and safety assurances. With its environmentally friendly profile, GRP grating also supports sustainable construction practices, aligning with global trends towards reducing carbon footprints. For those considering GRP open mesh grating, the decision is not just about choosing a superior material; it's about investing in a solution that guarantees reliability and performance. The product's ability to withstand diverse environmental challenges, combined with its adaptability and low lifecycle costs, make it an indisputable choice for modern infrastructure needs. As industries strive to improve safety standards and operational efficiency, GRP open mesh grating is poised to play a pivotal role in shaping the future of industrial design and safety.

Authoritative sources, including engineering reports and safety audits, highlight GRP grating's superior performance over traditional materials. Studies have demonstrated its resistance to fire, chemicals, and UV radiation, underscoring its applicability in stringent environments. Furthermore, global standards such as those from ASTM and ISO provide guidelines that GRP grating products adhere to, ensuring compliance and quality assurance. In terms of experience, users of GRP open mesh grating report significant benefits including long-term cost savings due to reduced maintenance requirements. The lightweight nature of GRP grating simplifies installation procedures, allowing for quicker project completion and less labor-intensive processes. This efficiency translates to reduced operational downtime, enhancing productivity. Trustworthiness is further amplified through the product's traceable supply chain and rigorous quality control measures. Leading manufacturers offer extensive warranties and certification, ensuring that end-users receive a product that upholds both performance promises and safety assurances. With its environmentally friendly profile, GRP grating also supports sustainable construction practices, aligning with global trends towards reducing carbon footprints. For those considering GRP open mesh grating, the decision is not just about choosing a superior material; it's about investing in a solution that guarantees reliability and performance. The product's ability to withstand diverse environmental challenges, combined with its adaptability and low lifecycle costs, make it an indisputable choice for modern infrastructure needs. As industries strive to improve safety standards and operational efficiency, GRP open mesh grating is poised to play a pivotal role in shaping the future of industrial design and safety.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024