loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

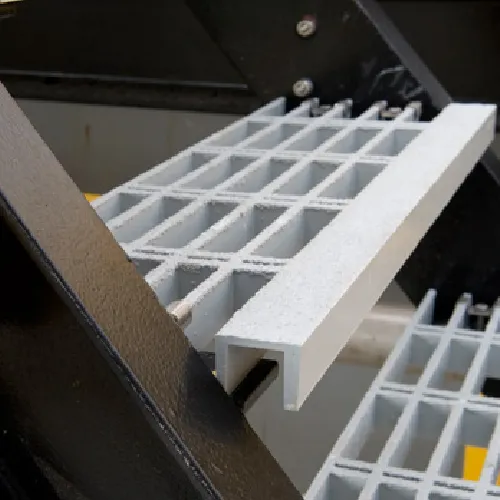

Pultruded Grating Solutions for Enhanced Structural Performance and Durability

Understanding GRP Pultruded Grating A Comprehensive Overview

Glass Reinforced Plastic (GRP) pultruded grating is an innovative material that has gained significant popularity across various industries due to its unique properties and advantages. Combining the strength of glass fibers with the lightweight characteristics of plastics, GRP pultruded grating is engineered to meet the demanding requirements of modern applications, including construction, wastewater treatment, marine environments, and more.

Pultrusion is a manufacturing process that involves pulling together fibers and resins to create a continuous profile, which is then cured to achieve its final form. This method allows for the production of strong, lightweight, and corrosion-resistant grating that can endure harsh conditions without succumbing to physical degradation. The tensile strength of GRP pultruded grating makes it an ideal choice for load-bearing applications while remaining significantly lighter than traditional materials like steel or aluminum.

Understanding GRP Pultruded Grating A Comprehensive Overview

In terms of safety, GRP pultruded grating offers excellent slip resistance, making it a preferred choice for flooring solutions in industrial and commercial settings. The surface can be designed with anti-slip features, ensuring a secure footing even in wet or oily conditions. This is particularly vital in environments such as factories, where the risk of slips and falls can lead to accidents and injuries.

grp pultruded grating

Another significant advantage of GRP pultruded grating is its versatility. It can be manufactured in various sizes, shapes, and colors to suit specific project requirements. Whether for walkways, platforms, or custom installations, GRP grating can be tailored to meet the architectural and functional needs of the project. Additionally, it can be prefabricated, allowing for quicker installation on-site, which can be essential in projects requiring tight schedules.

The environmental impact of GRP pultruded grating is another component worth considering. Being inherently resistant to rot, mold, and UV degradation, GRP helps reduce the need for chemical treatments and paints, making it a more sustainable choice. Its lightweight nature also contributes to lower transportation emissions, as more material can be loaded onto a single shipment compared to heavier counterparts.

Cost-effectiveness is a crucial factor in any material selection, and GRP pultruded grating offers competitive pricing when considering its lifespan and minimal maintenance requirements. While the initial investment may be on par with or slightly higher than traditional materials, the long-term savings in maintenance, replacement, and safety make it a wise choice.

In conclusion, GRP pultruded grating stands out as a formidable material option in various industries due to its strength, durability, safety features, and environmental benefits. As industries continue to seek materials that meet both performance and cost-efficiency criteria, GRP pultruded grating is likely to become an even more prevalent choice, paving the way for innovative solutions in engineering and construction. Whether for a large-scale industrial project or specialized applications, GRP pultruded grating is a definitive choice that combines quality with functionality.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024