loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 19, 2025 11:38

Back to list

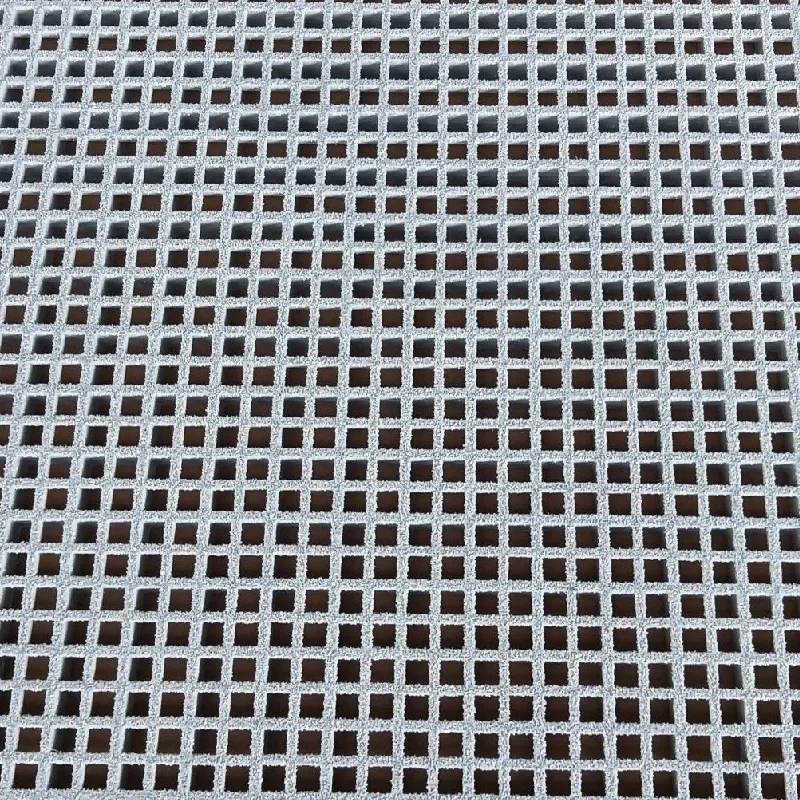

Smaller Open Mesh Area FRP Mini Mesh Grating

Enhancing facility safety and efficiency often involves selecting the right materials for infrastructure applications. GRP pultruded grating stands out in industrial settings, offering a blend of durability, flexibility, and cost efficiency that other materials struggle to match. This specialized grating is made from glass-reinforced plastic, a composite that ensures resilience against environmental stresses while maintaining a lightweight structure. Through a detailed exploration, we'll uncover why GRP pultruded grating is swiftly becoming the preferred choice for industries worldwide.

Electrical and thermal insulation properties are additional benefits that place GRP pultruded grating ahead of traditional materials like steel or aluminum. This insulation capability is particularly advantageous in electrical environments, where eliminating conductivity can prevent accidents. Similarly, its thermal non-conductivity allows it to remain stable under fluctuating temperatures, preserving workplace safety and product integrity in extreme settings. Adopting GRP pultruded grating aligns well with contemporary sustainability goals. Its production involves less environmental impact compared to metals, and the material itself is long-lasting, resisting the need for frequent replacements. Furthermore, given its durability, the energy and resources used over its life cycle are minimized, supporting eco-friendly initiatives. Industries benefiting from GRP pultruded grating range widely, including manufacturing, petrochemical, marine, and even recreational sectors. The adaptability of GRP to diverse environmental and structural demands makes it a versatile candidate for myriad applications. Moreover, customization options such as different colors and shapes ensure that aesthetic and functional demands are met concurrently. In summary, GRP pultruded grating proves to be an optimal solution for enhancing structural applications in challenging environments. Its corrosion resistance, strength-to-weight ratio, safety features, and insulation properties provide industries with a multifaceted material that champions reliability and efficiency. As a sustainable, long-term investment, GRP pultruded grating not only meets today's industrial needs but also pioneers the trajectory for future innovations. Industries globally are recognizing its unmatched utility, making it not just an alternative but a preferred choice for infrastructure and safety-critical applications.

Electrical and thermal insulation properties are additional benefits that place GRP pultruded grating ahead of traditional materials like steel or aluminum. This insulation capability is particularly advantageous in electrical environments, where eliminating conductivity can prevent accidents. Similarly, its thermal non-conductivity allows it to remain stable under fluctuating temperatures, preserving workplace safety and product integrity in extreme settings. Adopting GRP pultruded grating aligns well with contemporary sustainability goals. Its production involves less environmental impact compared to metals, and the material itself is long-lasting, resisting the need for frequent replacements. Furthermore, given its durability, the energy and resources used over its life cycle are minimized, supporting eco-friendly initiatives. Industries benefiting from GRP pultruded grating range widely, including manufacturing, petrochemical, marine, and even recreational sectors. The adaptability of GRP to diverse environmental and structural demands makes it a versatile candidate for myriad applications. Moreover, customization options such as different colors and shapes ensure that aesthetic and functional demands are met concurrently. In summary, GRP pultruded grating proves to be an optimal solution for enhancing structural applications in challenging environments. Its corrosion resistance, strength-to-weight ratio, safety features, and insulation properties provide industries with a multifaceted material that champions reliability and efficiency. As a sustainable, long-term investment, GRP pultruded grating not only meets today's industrial needs but also pioneers the trajectory for future innovations. Industries globally are recognizing its unmatched utility, making it not just an alternative but a preferred choice for infrastructure and safety-critical applications.

Share

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024