loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

2 月 . 18, 2025 09:00

Back to list

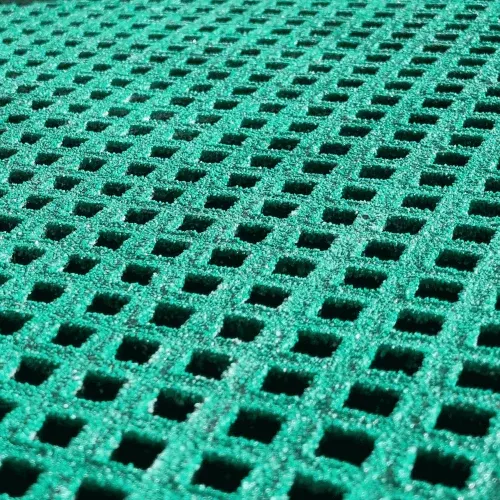

grp mini mesh grating

Glass Reinforced Plastic (GRP) sandwich panels are revolutionizing the construction industry with their unique blend of strength, durability, and lightweight properties. These innovative panels are crafted by combining thin layers of GRP with a core material, often composed of polyurethane foam, polystyrene, or other lightweight, insulating substances. This combination yields a product that is not only robust and resilient but also offers excellent thermal and acoustic insulation properties, making it ideal for a myriad of applications.

Trustworthiness is inherently built into GRP sandwich panels through their stringent manufacturing processes and adherence to global safety standards. Manufacturers subject these panels to rigorous testing to ensure they meet the required specifications for strength, fire resistance, and thermal efficiency. Certifications from credible bodies provide an additional layer of assurance that the GRP sandwich panels will perform reliably under a variety of conditions, guaranteeing peace of mind to both contractors and end-users. Beyond their mechanical advantages, GRP sandwich panels support sustainable building practices. Their core materials are often recyclable, and the panels themselves contribute to lower energy consumption due to their insulating properties. This aligns with the growing trend towards eco-friendly construction solutions, where reducing carbon footprints and promoting energy efficiency are paramount. Moreover, GRP sandwich panels can be custom-engineered to meet specific aesthetic and functional requirements. They can be produced in a variety of finishes and textures, allowing for creative architectural designs that do not compromise on performance. This customization capability makes them highly sought-after in projects where visual appeal is as important as structural robustness. In conclusion, the rise of GRP sandwich panels in the construction industry marks a significant shift towards smarter, more innovative building solutions. Their unmatched strength-to-weight ratio, coupled with exceptional insulating properties, positions them as the material of choice for the forward-thinking architect or engineer. The combination of real-world applications and authoritative backing not only underscores their efficacy but also builds trust among users, ensuring that the adoption of GRP sandwich panels will continue to grow as more industries recognize their vast potential.

Trustworthiness is inherently built into GRP sandwich panels through their stringent manufacturing processes and adherence to global safety standards. Manufacturers subject these panels to rigorous testing to ensure they meet the required specifications for strength, fire resistance, and thermal efficiency. Certifications from credible bodies provide an additional layer of assurance that the GRP sandwich panels will perform reliably under a variety of conditions, guaranteeing peace of mind to both contractors and end-users. Beyond their mechanical advantages, GRP sandwich panels support sustainable building practices. Their core materials are often recyclable, and the panels themselves contribute to lower energy consumption due to their insulating properties. This aligns with the growing trend towards eco-friendly construction solutions, where reducing carbon footprints and promoting energy efficiency are paramount. Moreover, GRP sandwich panels can be custom-engineered to meet specific aesthetic and functional requirements. They can be produced in a variety of finishes and textures, allowing for creative architectural designs that do not compromise on performance. This customization capability makes them highly sought-after in projects where visual appeal is as important as structural robustness. In conclusion, the rise of GRP sandwich panels in the construction industry marks a significant shift towards smarter, more innovative building solutions. Their unmatched strength-to-weight ratio, coupled with exceptional insulating properties, positions them as the material of choice for the forward-thinking architect or engineer. The combination of real-world applications and authoritative backing not only underscores their efficacy but also builds trust among users, ensuring that the adoption of GRP sandwich panels will continue to grow as more industries recognize their vast potential.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024