loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Exploring the Dynamics and Applications of Group Structures in Modern Mathematics

Understanding GRP Structures A Comprehensive Overview

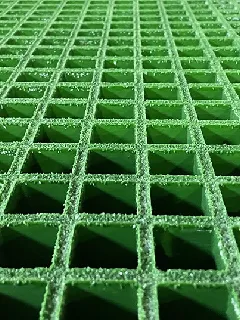

GRP, or Glass Reinforced Plastic, is a composite material known for its versatile applications and exceptional properties. It combines glass fibers with a plastic resin, typically polyester or vinylester, resulting in a lightweight yet strong material ideal for various structural applications. GRP structures have gained significant traction in multiple industries, including construction, automotive, aerospace, marine, and telecommunications, due to their superior mechanical properties and resistance to environmental factors.

One of the primary advantages of GRP structures is their excellent strength-to-weight ratio. The incorporation of glass fibers into the resin matrix imparts remarkable rigidity and tensile strength, making GRP structures robust yet lightweight. This property is particularly valuable in construction and infrastructure projects, where reducing weight can lead to lower transportation costs and simpler installation processes while maintaining structural integrity.

Another benefit of GRP structures is their resistance to corrosion and environmental degradation. Unlike traditional materials, such as steel or wood, GRP does not rust or rot. This characteristic makes GRP an ideal choice for applications exposed to harsh environmental conditions, such as chemical processing plants, offshore platforms, and wastewater treatment facilities. The longevity of GRP structures can result in significant cost savings over time, as maintenance and replacement expenditures are minimized.

Understanding GRP Structures A Comprehensive Overview

Another noteworthy aspect of GRP structures is their adaptability to various design requirements. The manufacturing process for GRP allows for customizable shapes and sizes, enabling designers to create complex geometries that would be challenging with traditional materials. This flexibility has led to innovative architectural designs and infrastructure developments. From curved bridges to uniquely shaped building facades, GRP is pushing the boundaries of contemporary design.

grp structures

Despite its numerous advantages, the production of GRP structures is not without challenges. The manufacturing process can be energy-intensive, and the resin used may release volatile organic compounds (VOCs) into the atmosphere during curing. However, advancements in technology and the development of eco-friendly resins are helping to mitigate these concerns. Manufacturers are increasingly adopting sustainable practices, such as recycling waste materials and exploring bio-based resins to reduce the environmental impact of GRP production.

The application of GRP structures is extensive and varied. In the construction industry, GRP is used for roofing panels, cladding, and gratings. Its lightweight nature simplifies installation and reduces the load on underlying structures. In the transportation sector, GRP components are found in the manufacturing of bodies for buses, trains, and ships, where weight reduction contributes to improved fuel efficiency.

Moreover, GRP's role in the telecommunications industry cannot be overstated. GRP is used to create enclosures, cabinets, and poles for transmitting equipment. Its properties protect sensitive equipment from environmental factors while ensuring reliable performance. In the renewable energy sector, GRP has found applications in wind turbine blades—its lightweight and sturdy design enhances the efficiency of energy generation.

Looking towards the future, the demand for GRP structures is expected to continue rising, driven by the need for lightweight, durable, and corrosion-resistant solutions across various sectors. Ongoing research and technological innovations will likely expand the potential applications of GRP, further solidifying its position as a material of choice for many engineers and designers.

In conclusion, GRP structures represent a significant advancement in material science, offering a blend of strength, durability, and design flexibility. As industries evolve and face new challenges, the role of GRP in providing innovative solutions will undoubtedly grow. Its applications are set to become even more prominent, making it a critical material for the future of engineering and construction. The potential of GRP structures is vast, and their impact will continue to inspire new ideas and developments in the years to come.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024