loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

hdg tank

Understanding HDG Tanks An Overview

In the modern industrial landscape, the use of various types of storage tanks plays a crucial role in the safe and efficient handling of liquids and gases. Among these, the Hot-Dip Galvanized (HDG) tank has gained significant popularity due to its durability, corrosion resistance, and long service life. This article aims to elucidate what HDG tanks are, their construction, advantages, applications, and maintenance, ensuring a comprehensive understanding of this essential equipment.

What is an HDG Tank?

A Hot-Dip Galvanized tank is a type of storage unit that has undergone a galvanization process, wherein steel or iron is immersed in molten zinc. This process creates a protective coating that significantly enhances the metal's ability to resist corrosion, oxidation, and rusting. The result is a robust and long-lasting storage solution that is especially suited for environments where moisture and harsh chemicals are prevalent.

Construction of HDG Tanks

The construction of HDG tanks typically involves the following steps

1. Material Selection High-grade steel or iron is chosen for its structural integrity.

2. Fabrication The metal sheets are cut and shaped to form the tank. This fabrication process may include welding, bending, and forming to achieve the desired design and size.

3. Hot-Dip Galvanization Once the tank has been fabricated, it is thoroughly cleaned to remove any contaminants. This is followed by immersing the tank in a zinc bath at a temperature of around 450 degrees Celsius. The zinc adheres to the surface, forming a metallurgical bond that provides exceptional corrosion resistance.

4. Finishing After the galvanization process, the tank may be subjected to additional finishing processes to enhance its aesthetic appeal and reduce any sharp edges or rough surfaces.

Advantages of HDG Tanks

hdg tank

1. Corrosion Resistance The primary benefit of HDG tanks is their exceptional resistance to corrosion. The zinc coating protects the underlying steel from moisture and chemicals, significantly extending the tank's lifespan compared to untreated steel.

2. Low Maintenance Due to their durable coating, HDG tanks require minimal maintenance. They do not need frequent repainting or protective coatings, reducing long-term operational costs.

3. Cost-Effectiveness While the initial investment may be higher than that of conventional tanks, the longevity and low maintenance requirements of HDG tanks ultimately make them a cost-effective choice over the years.

4. Versatility HDG tanks are suitable for a wide range of applications, including water storage, chemical storage, and fuel storage. Their robust design makes them adaptable to various industries, including agriculture, manufacturing, and petrochemical.

5. Environmental Impact By choosing HDG tanks, industries can contribute to environmental sustainability. The longer lifespan and reduced need for replacements mean less waste and lower resource consumption over time.

Applications of HDG Tanks

HDG tanks are widely used across various sectors. In the agricultural industry, they serve as reliable storage solutions for water and fertilizers. In municipal water management, HDG tanks provide safe storage for drinking water, ensuring compliance with health and safety regulations.

In the chemical industry, the resistance to corrosive substances makes these tanks ideal for storing acids and other reactive chemicals. Similarly, in the oil and gas sector, HDG tanks are utilized for storing fuels and other hydrocarbon products, where preventing leaks and spills is critical for safety and environmental protection.

Maintenance of HDG Tanks

While HDG tanks are designed for low maintenance, periodic inspections are essential to ensure their continued integrity. Operators should check for signs of physical damage, such as dents or scratches, that could compromise the coating. Regular cleaning helps prevent the buildup of contaminants that could lead to corrosion over time.

In conclusion, Hot-Dip Galvanized tanks represent a reliable solution for a variety of storage needs. Their combination of durability, resistance to corrosion, and low maintenance requirements make them an invaluable asset in numerous industries. As industries continue to evolve, the relevance of HDG tanks will only grow, serving as a testament to the innovation and efficiency in modern storage solutions.

-

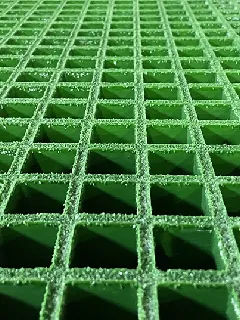

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024