loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

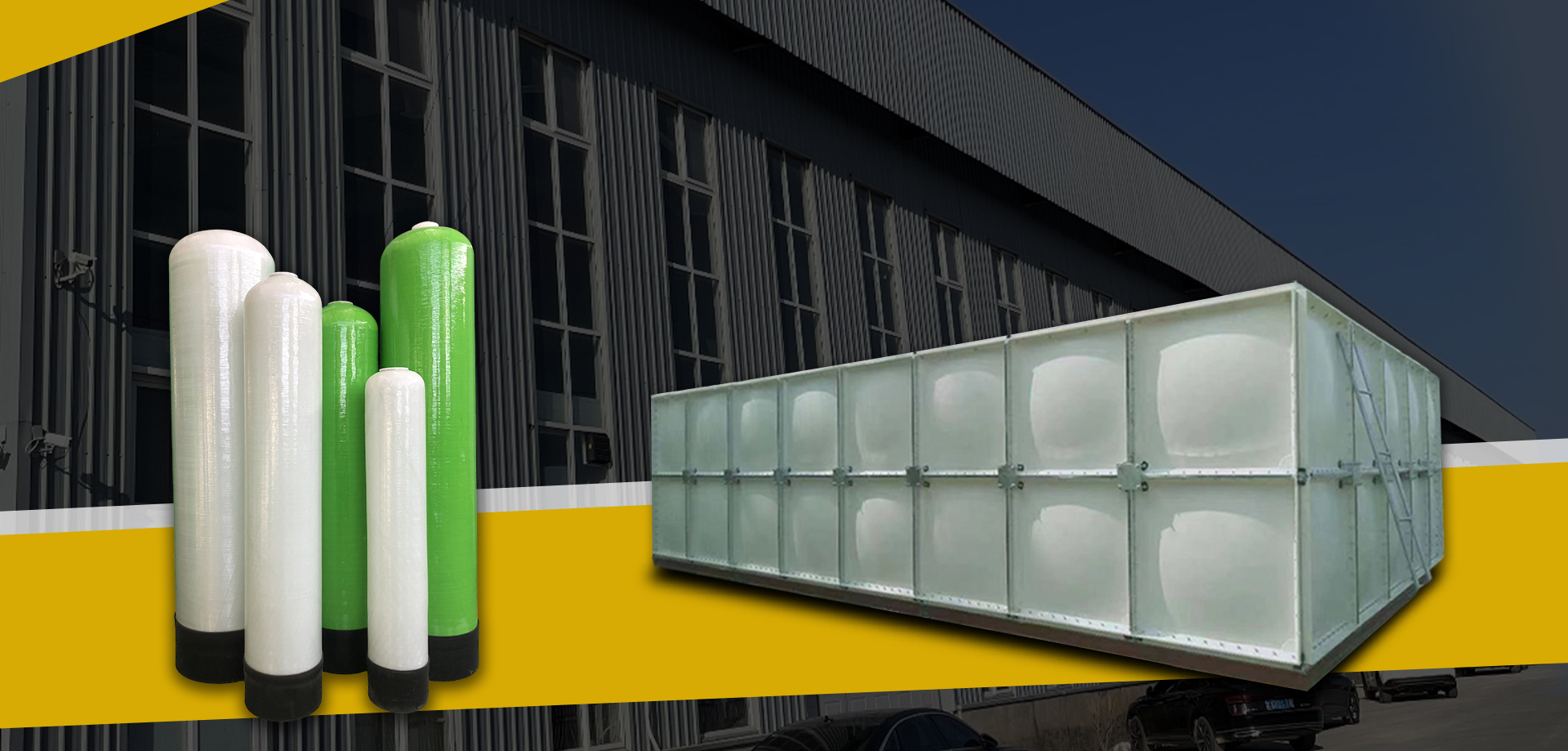

hdg tank

Understanding HDG Tanks Key Features and Applications

Hot-Dip Galvanizing (HDG) is a widely adopted process for protecting steel structures against corrosion, and it is particularly crucial in industries where durability and longevity are paramount. One notable application of this technology is in HDG tanks, which are used for various storage and containment purposes. This article explores the features, benefits, and applications of HDG tanks in different sectors.

What are HDG Tanks?

HDG tanks are storage units made of steel that have undergone the hot-dip galvanization process. This involves immersing the steel in molten zinc, creating a robust barrier that protects it from environmental aggressors such as moisture, chemicals, and other corrosive elements. The result is a durable tank that can withstand harsh conditions while maintaining structural integrity.

Key Features of HDG Tanks

1. Corrosion Resistance The primary advantage of HDG tanks is their exceptional corrosion resistance. The zinc coating acts as a sacrificial layer, providing long-lasting protection against rust and degradation, which is essential in outdoor and industrial environments.

2. Durability HDG tanks are known for their strength and durability. They can endure various mechanical stresses and impacts, making them suitable for heavy-duty applications.

3. Low Maintenance Due to their corrosion-resistant properties, HDG tanks require minimal maintenance over their lifetime. This translates to lower operational costs and less downtime, which is a significant benefit for businesses.

4. Environmentally Friendly The process of hot-dip galvanizing is environmentally friendly. Zinc is a naturally occurring element, and the process itself emits fewer pollutants than other methods of steel protection. Additionally, HDG tanks can be recycled at the end of their life cycle.

hdg tank

5. Versatility HDG tanks come in various sizes and designs, making them adaptable for multiple applications, including the storage of liquids, chemicals, and other materials.

Applications of HDG Tanks

HDG tanks find their application across a wide range of industries

- Water and Wastewater Treatment These tanks are used to store chemicals for water treatment, as well as for the containment of treated water, ensuring that the materials remain uncontaminated.

- Agriculture HDG tanks are commonly used in the agricultural sector for the storage of fertilizers, pesticides, and other chemicals, providing a reliable solution for farmers.

- Oil and Gas In the oil and gas industry, HDG tanks are used for the storage of fuels and other potentially hazardous materials, where corrosion resistance is particularly critical.

- Food and Beverage The food industry requires tanks that can safely contain ingredients and products. HDG tanks comply with hygiene regulations while providing the necessary durability.

Conclusion

In summary, HDG tanks represent a critical advancement in industrial storage technology. Their corrosion resistance, durability, low maintenance, and versatility make them invaluable assets across various sectors. As industries continue to emphasize sustainability and efficiency, the adoption of HDG tanks is likely to grow, further highlighting the importance of this innovative solution in modern infrastructure. Whether used for water treatment, agricultural purposes, or in the oil and gas sector, HDG tanks are indeed a reliable choice for ensuring the integrity and safety of stored materials.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024