loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1 月 . 20, 2025 09:36

Back to list

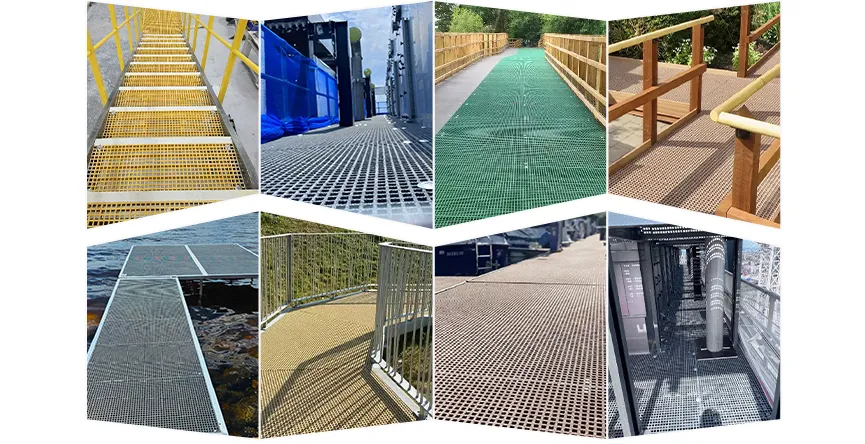

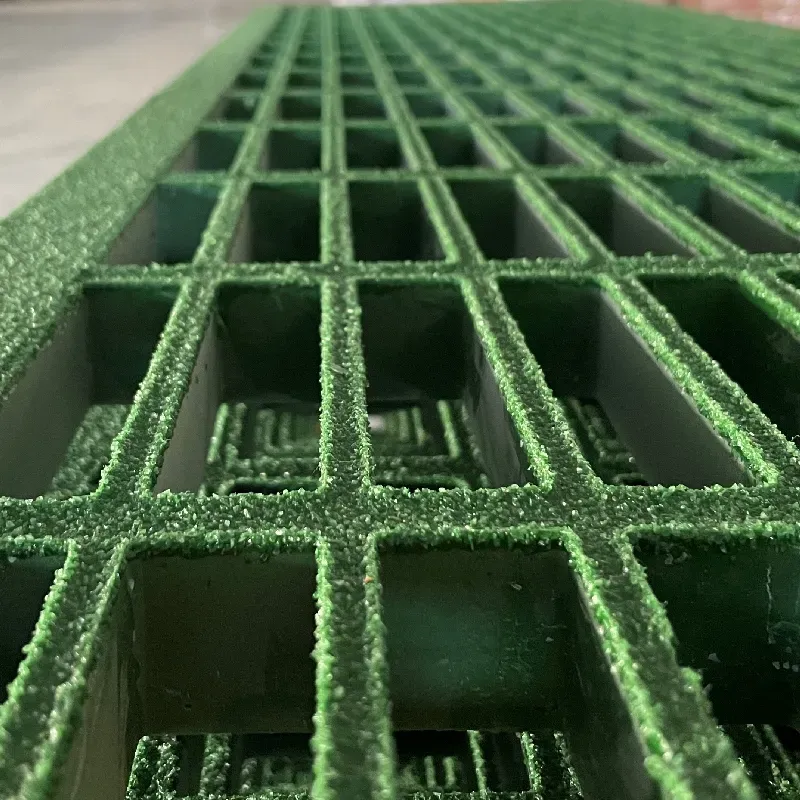

frp micro mesh grating

Heavy duty bar grating serves as a fundamental component in various industrial and architectural applications, renowned for its durability, strength, and versatility. This robust grating solution finds utility in environments that demand resilience under substantial foot and vehicular traffic. Here are several insights into why heavy duty bar grating stands out as the optimal choice and how to effectively integrate it into your project for enhanced functionality and safety.

Installation of heavy duty bar grating should be executed with precision to maximize its benefits. Ensuring proper anchoring and securing of the grating is essential to prevent any unintended dislocation or movement during use, which could potentially lead to accidents. Employing professionals with expertise in handling and installing heavy duty grating can significantly enhance the safety and longevity of the installation. Maintenance considerations also play a crucial role in the lifecycle of heavy duty bar grating. Regular inspections to check for any damage or wear can preempt potential issues, while proper cleaning methods will help maintain the integrity and appearance of the grating. Materials like stainless steel require minimal maintenance compared to their counterparts, proving to be a wise investment in the long term. Heavy duty bar grating's adaptability also extends to customization options, allowing it to meet the precise specifications of complex architectural designs. Patterns, finishes, and dimensions can be tailored to complement the aesthetic and functional requirements of a project, thereby making heavy duty bar grating not only a practical solution but also an aesthetically pleasing one. In conclusion, heavy duty bar grating's robust design, high load-bearing capacity, and adaptability make it an indispensable component in demanding applications. Through informed selection, proper installation, and regular maintenance, heavy duty bar grating can enhance the safety, efficiency, and lifespan of various structural projects. As trends in construction and industrial design continue to evolve, the application of heavy duty bar grating will undoubtedly remain integral, solidifying its status as a cornerstone in modern infrastructure solutions.

Installation of heavy duty bar grating should be executed with precision to maximize its benefits. Ensuring proper anchoring and securing of the grating is essential to prevent any unintended dislocation or movement during use, which could potentially lead to accidents. Employing professionals with expertise in handling and installing heavy duty grating can significantly enhance the safety and longevity of the installation. Maintenance considerations also play a crucial role in the lifecycle of heavy duty bar grating. Regular inspections to check for any damage or wear can preempt potential issues, while proper cleaning methods will help maintain the integrity and appearance of the grating. Materials like stainless steel require minimal maintenance compared to their counterparts, proving to be a wise investment in the long term. Heavy duty bar grating's adaptability also extends to customization options, allowing it to meet the precise specifications of complex architectural designs. Patterns, finishes, and dimensions can be tailored to complement the aesthetic and functional requirements of a project, thereby making heavy duty bar grating not only a practical solution but also an aesthetically pleasing one. In conclusion, heavy duty bar grating's robust design, high load-bearing capacity, and adaptability make it an indispensable component in demanding applications. Through informed selection, proper installation, and regular maintenance, heavy duty bar grating can enhance the safety, efficiency, and lifespan of various structural projects. As trends in construction and industrial design continue to evolve, the application of heavy duty bar grating will undoubtedly remain integral, solidifying its status as a cornerstone in modern infrastructure solutions.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024