loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

3 月 . 07, 2025 03:21

Back to list

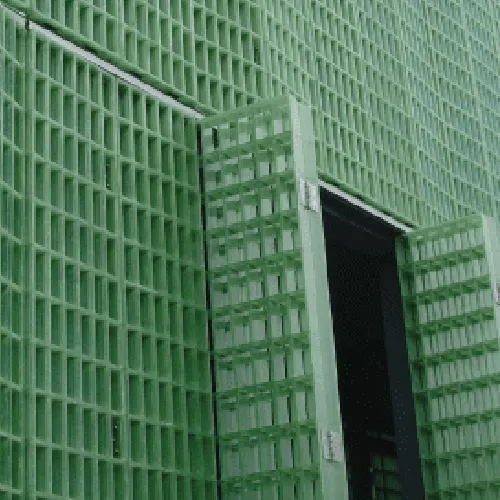

frp micro mesh grating

Heavy-duty bar grating serves as a cornerstone for industrial applications requiring resilience, durability, and enhanced safety measures. Serving various sectors from manufacturing to energy, this product's key attributes are indispensable for facilities aiming to sustain heavy foot and equipment traffic.

From an installation perspective, heavy-duty bar grating offers significant advantages. Its lightweight nature compared to solid flooring materials simplifies handling and reduces the logistical complexity of installation. Whether welded or fastened, the grating can be installed with minimal tools and effort, making it a cost-effective choice for large-scale projects. Maintenance is another area where heavy-duty bar grating shines. The design minimizes the accumulation of dirt and debris, which reduces maintenance time and extends the product's lifespan. This durability is not merely anecdotal; manufacturers frequently back their products with extended warranties, proving the grating's longevity even under the most challenging conditions. Regular inspections ensure ongoing safety, but the structural integrity of heavy-duty bar grating rarely wanes over time. Through decades of application, heavy-duty bar grating has cultivated a reputation for excellence, underscored by endorsements from engineers and safety experts alike. Its alignment with robust safety standards, such as those set by the Occupational Safety and Health Administration (OSHA), further solidifies its status as a go-to solution for industrial flooring. The safe, reliable foundation it provides is invaluable for companies striving for optimum operational efficiency and safety compliance. In conclusion, heavy-duty bar grating stands out not only for its structural benefits but also for its contribution to safety and efficiency. Its proven performance across a range of demanding environments underscores its essential role in modern industry. Decision-makers seeking flooring solutions that balance quality, performance, and cost will find an unmatched ally in heavy-duty bar grating. Its adaptability and resilience empower industries to meet the demands of today while preparing for the challenges of tomorrow.

From an installation perspective, heavy-duty bar grating offers significant advantages. Its lightweight nature compared to solid flooring materials simplifies handling and reduces the logistical complexity of installation. Whether welded or fastened, the grating can be installed with minimal tools and effort, making it a cost-effective choice for large-scale projects. Maintenance is another area where heavy-duty bar grating shines. The design minimizes the accumulation of dirt and debris, which reduces maintenance time and extends the product's lifespan. This durability is not merely anecdotal; manufacturers frequently back their products with extended warranties, proving the grating's longevity even under the most challenging conditions. Regular inspections ensure ongoing safety, but the structural integrity of heavy-duty bar grating rarely wanes over time. Through decades of application, heavy-duty bar grating has cultivated a reputation for excellence, underscored by endorsements from engineers and safety experts alike. Its alignment with robust safety standards, such as those set by the Occupational Safety and Health Administration (OSHA), further solidifies its status as a go-to solution for industrial flooring. The safe, reliable foundation it provides is invaluable for companies striving for optimum operational efficiency and safety compliance. In conclusion, heavy-duty bar grating stands out not only for its structural benefits but also for its contribution to safety and efficiency. Its proven performance across a range of demanding environments underscores its essential role in modern industry. Decision-makers seeking flooring solutions that balance quality, performance, and cost will find an unmatched ally in heavy-duty bar grating. Its adaptability and resilience empower industries to meet the demands of today while preparing for the challenges of tomorrow.

Share

Next:

Latest news

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024