loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Durable Load-Bearing Bar Grating Solutions for Industrial Applications and Heavy Machinery

Understanding Heavy Duty Bar Grating Applications, Benefits, and Maintenance

Heavy duty bar grating is a crucial component in various industries, providing strength, safety, and durability in environments that demand high performance. This article explores the significance of heavy duty bar grating, its applications, benefits, and maintenance to ensure optimal performance over time.

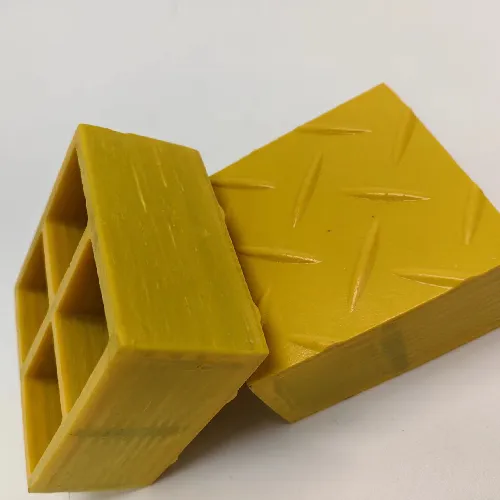

What is Heavy Duty Bar Grating?

Heavy duty bar grating is a type of flooring or platform made from steel or other materials, fabricated with load-bearing bars spaced at regular intervals. This grating is designed to withstand heavy loads, making it ideal for industrial settings, transportation infrastructure, and even architectural applications. The bars can be made from various materials, including carbon steel, aluminum, and stainless steel, each offering different benefits depending on the specific requirements of the installation.

Applications of Heavy Duty Bar Grating

One of the primary applications of heavy duty bar grating is in the industrial sector. Factories, warehouses, and manufacturing plants often utilize this grating for walkways, platforms, and drainage covers due to its ability to handle significant weight without compromising safety. In addition, heavy duty bar grating is commonly used in

1. Drainage Systems Bar grating can cover drainage channels while allowing water to flow freely, preventing flooding and ensuring a safe working environment. 2. Walkways and Platforms High-traffic areas in industrial settings benefit from the strength and anti-slip properties of heavy duty bar grating, reducing the risk of accidents.

3. Heavy Machinery Support In environments where heavy machinery is prevalent, bar grating provides a stable and robust surface for equipment and vehicles.

4. Utility Access Many utility companies use heavy duty bar grating to create access points to underground lines while ensuring safety for pedestrians and vehicles above.

5. Architectural Applications Beyond industrial uses, heavy duty bar grating is also employed in architectural settings, such as in bridges and building facades, where both strength and aesthetic appeal are essential.

Benefits of Heavy Duty Bar Grating

The advantages of using heavy duty bar grating are numerous, making it a preferred choice for many applications

- High Load Capacity Designed to withstand substantial weight, heavy duty bar grating can support both pedestrian and vehicular traffic without deformation.

heavy duty bar grating

- Durability When made from quality materials, heavy duty bar grating can resist corrosion, extreme temperatures, and other environmental factors that can lead to wear and tear.

- Safety Features With options for anti-slip surfaces and excellent drainage, heavy duty bar grating enhances safety in workplaces, preventing slips and falls.

- Cost-Effective Given its longevity and low maintenance requirements, heavy duty bar grating represents a worthwhile investment for businesses that need reliable flooring solutions.

- Versatility Available in different materials, sizes, and load capacities, heavy duty bar grating can be customized to meet specific application requirements.

Maintenance of Heavy Duty Bar Grating

To maintain the integrity and performance of heavy duty bar grating, regular inspection and maintenance are essential. Here are some key maintenance tips

1. Regular Inspections Check for signs of wear, corrosion, or damage regularly, especially in areas exposed to harsh environmental conditions.

2. Cleaning Keep the grating clean to prevent the buildup of debris, which can cause slippery surfaces and hinder drainage capabilities.

3. Rust Prevention For steel grating, ensure that protective coatings are intact and address any signs of rust immediately to prolong the lifespan of the structure.

4. Load Assessment Periodically evaluate the load distribution and ensure that the grating is not subjected to loads beyond its capacity.

5. Prompt Repairs If any damage is detected, repair or replace the affected sections promptly to maintain safety standards.

Conclusion

Heavy duty bar grating serves as an essential solution across various industries, providing durability, safety, and efficiency. By understanding its applications, benefits, and maintenance needs, businesses can ensure they maximize the value obtained from their investments in this crucial structural element. Whether for industrial, commercial, or architectural purposes, heavy duty bar grating remains a dependable choice for those seeking reliability in demanding environments.

-

Transform Your Spaces with FRP Grating SolutionsNewsNov.04,2024

-

The Versatility and Strength of FRP RodsNewsNov.04,2024

-

The Excellence of Fiberglass Water TanksNewsNov.04,2024

-

The Benefits of FRP Grating for Your ProjectsNewsNov.04,2024

-

Elevate Your Efficiency with FRP Pressure VesselsNewsNov.04,2024

-

Welcome to the World of FRP Pressure VesselsNewsOct.12,2024

-

Unveiling the Future of Filtration: Why FRP Filter Vessels are a Game ChangerNewsOct.12,2024